by James | May 6, 2023 | Welding

Welding beads, also known as weld beads, are long streaks of molten metal created in the welding process when two separate pieces of metal are melted together. Welding beads provide various benefits and are used in many industrial processes and applications.

In this comprehensive guide, we’ll take you through the basics of welding beads. From construction to car manufacturing, welding beads are an essential part of the welding process. Understanding the basics and knowing how to use them properly can save time and money while ensuring a quality product. Let’s get started!

What are Welding Beads?

Welding beads are an essential aspect of welding. A welding bead is a thin layer of metal that is fused to the workpiece during the welding process. The bead is created by melting the base metal and the filler material together. The bead’s shape and appearance can provide insight into the welder’s skill and the quality of the weld.

Understanding the Different Types of welding beads

There are several types of welding beads, each with its unique characteristics and applications. Here are some of the most common types:

- Flat Weld Bead: This type of weld bead is characterized by a flat surface and is used to join two plates of equal thickness.

- Fillet Weld Bead: A fillet weld is a triangular-shaped bead that is used to join two pieces of metal at an angle. It is commonly used in construction and fabrication applications.

- Butt Weld Bead: This type of weld bead is used to join two pieces of metal end to end. It can be made with or without filler metal.

- Plug Weld Bead: A plug weld is a type of weld bead that is used to join two pieces of metal that overlap. It is typically made by drilling a hole in one piece of metal and welding the other piece to it through the hole.

- Seam Weld Bead: A seam weld is a continuous weld bead that runs along the length of a joint. It is commonly used in piping and sheet metal fabrication applications.

- Spot Weld Bead: A spot weld is a type of weld bead that is used to join two pieces of metal by applying heat and pressure to a small area. It is commonly used in automotive and sheet metal fabrication applications.

- Back Weld Bead: A back weld is a type of weld bead that is used to reinforce the back side of a joint. It is commonly used in pipe welding applications.

These are just some of the most common types of welding beads. Other types include edge welds, surfacing welds, and overlay welds. The type of welding bead used will depend on the specific application and the materials being welded.

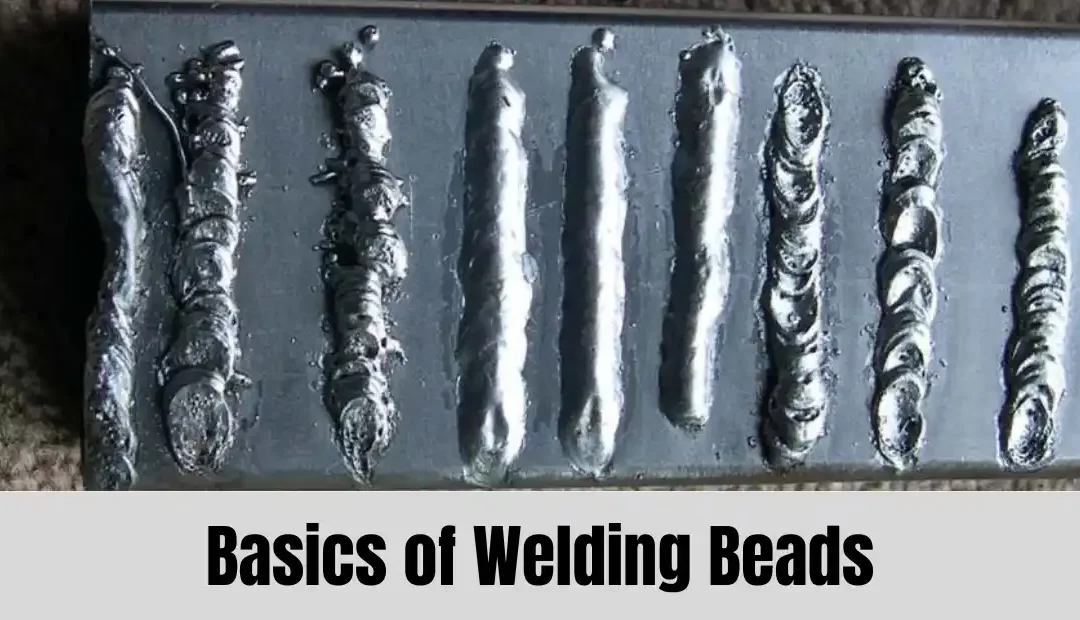

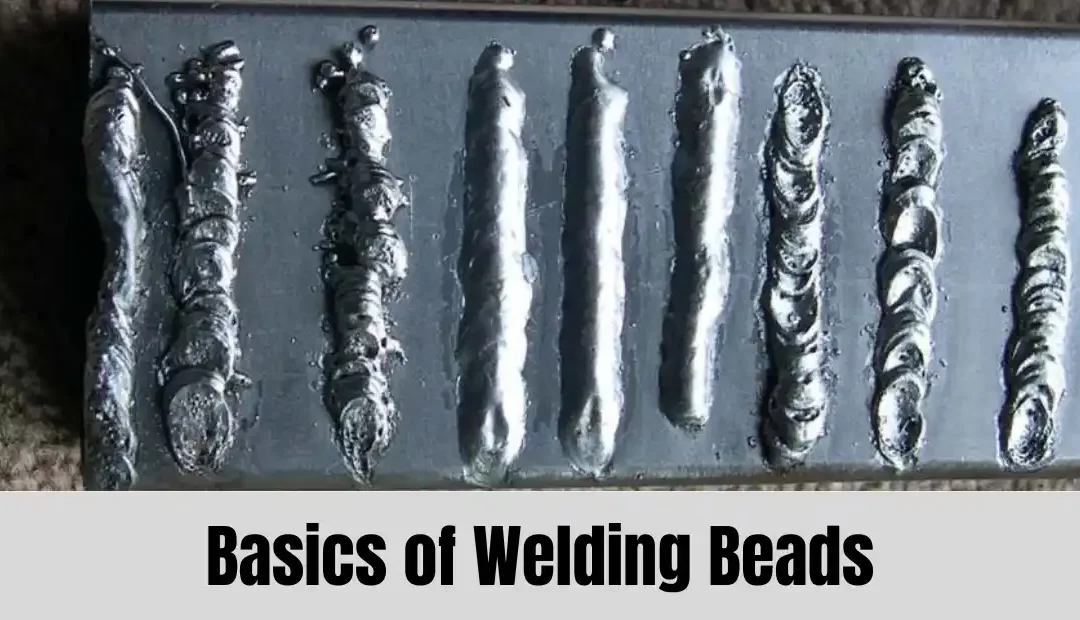

Patterns of Welding Beads

Sure, here are some common welding beads patterns:

- Stringer Bead: This is the simplest and most commonly used welding bead pattern. It is a straight line of weld deposited along the joint between the two pieces of metal. The stringer bead is used to make a strong and consistent weld.

- Weave Bead: This welding bead pattern involves moving the welding torch in a zig-zag motion while depositing the weld metal. This pattern is used to create a wider and stronger weld that covers a larger area than a stringer bead.

- Circle Bead: This welding bead pattern involves depositing the weld metal in a circular motion. This pattern is used when welding in a circular or curved joint to ensure even and consistent weld penetration.

- Figure 8 Bead: This welding bead pattern is similar to the circle bead pattern but involves depositing the weld metal in a figure-8 motion. This pattern is used when welding in a joint that requires multiple passes, and it helps to ensure even and consistent weld penetration.

- J Bead: This welding bead pattern involves depositing the weld metal in the shape of a “J” along the edge of one piece of metal. This pattern is used when joining two pieces of metal at a right angle and helps to ensure good penetration along the joint.

Choosing the Right Welding Rod for Your Welding Beads

When it comes to creating high-quality welding beads, choosing the right welding rod is essential. There are several factors to consider to ensure that you choose the right welding rod for your specific needs.

- Material Type and Thickness: The type and thickness of the material you are welding will dictate the type of welding rod you should use. For example, if you are welding thick pieces of steel, you will need a rod with a high amperage rating.

- Welding Position: The position in which you are welding (flat, horizontal, vertical, overhead) will also play a role in which welding rod you should choose. For example, if you are welding in an overhead position, you will need a welding rod that provides good penetration and can be controlled easily.

- Coating Type: Welding rods come coated with different substances to provide different benefits, such as easier striking, smoother welds, or enhanced strength. Understanding the different coating types and their benefits can help you choose the right rod for your specific welding needs.

When selecting a welding rod, it’s important to consult the manufacturer’s recommendations or speak with a welding expert if you are unsure which rod to choose.

Proper Cleaning and Preparation for Welding Beads

When it comes to welding beads, proper cleaning, and preparation are key to achieving a successful and high-quality weld. Here are some important steps to follow before starting the welding process:

- Remove any rust, oil, or debris from the surface area before welding. This can be done using a wire brush, angle grinder, or other suitable tools.

- Determine the type of metal you will be welding and clean it accordingly. Different metals require different cleaning methods, so it is important to choose the right one for the job. For example, aluminum should be cleaned with a dedicated aluminum cleaner, while stainless steel should be cleaned with a stainless steel cleaner.

- Check for any signs of contamination or impurities in the metal. This can be done using a magnet, which will not stick to pure metal but may stick to contaminated metal.

- Properly align and fit the metal pieces together. This will ensure that the weld is strong and secure.

- Use a suitable welding technique and equipment for the type of metal and thickness being welded. This can vary depending on the project, so it is important to choose the right technique and equipment for the job at hand.

By following these steps, you can ensure that your welds are of high quality and will last for a long time. Proper cleaning and preparation may take extra time and effort, but it is well worth it in the end.

Bead Welding Techniques: Tips and Tricks for Success

Welding beads are formed by the additional material that melts and fills the gap between two metal pieces. In welding, bead size, shape, and quality can indicate the weld’s strength and integrity. Welding bead techniques vary depending on the metal type, joint type, welding method, and position.

Here are some tips and tricks to achieve successful welding beads:

- Clean the metal surfaces: Before welding, it is essential to remove any rust, oil, paint, or debris that hinders the welding process and compromises the quality of the weld. Use a wire brush, grinder, or chemical cleaning solution to eliminate dirt and grime.

- Select the right electrode: Different metal types require specific electrodes to ensure a strong and successful weld. Electrodes come in various sizes, coatings, and materials, so ensure you use the one that matches the metal type and joint type.

- Adjust the welding parameters: Welding parameters such as voltage, amperage, travel speed, and arc length can significantly impact the bead shape, size, and penetration. Follow the manufacturer’s recommendations and adjust the parameters according to the metal thickness and joint type.

- Maintain the correct travel speed: The ideal travel speed is critical to achieving a consistent bead size and shape. Moving too fast or too slow can result in a flawed weld, including undercutting, spattering, and lack of penetration.

- Use proper technique: Welding technique is crucial to producing good welds and achieving a consistent bead appearance. Ensure your technique is steady, and your hands are stable. Keep the electrode near perpendicular to the workpiece and maintain a consistent arc length.

- Maintain appropriate heat input: Heat input impacts the weld bead’s size and shape. Too much heat input can cause distortion or burn-through, while too little heat input may result in insufficient penetration or incomplete fusion in the joint.

Remember, practice makes perfect; it may take some practice to master these techniques, but with time, you can produce beautiful, strong welding beads.

Advancements and Innovations in Welding Beads

Welding beads have been a staple of metalworking for many years, but recent advances in technology have led to some exciting innovations in this field. Let’s take a look at some of the recent advancements and how they are changing the game for welding beads.

- Laser Welding Beads: Laser welding is an innovative method that utilizes high-powered lasers to melt metal surfaces together. It is a high-speed, precision process that allows for clean, efficient welds without leaving behind any excess materials or byproducts.

- Cold Welding Beads: Cold welding is a type of welding that uses pressure to fuse metal surfaces together without the need for additional heat or solder. This process is ideal for materials that can’t withstand high temperatures or for situations where heat could damage nearby components.

- Robotics: Advances in robotics have made it possible to automate many welding tasks, which can improve efficiency and accuracy while reducing the risk of human error.

- Virtual Reality: Virtual reality technology is being used to simulate welding environments, which can help train new welders and improve safety on job sites.

- High-Speed Cameras: High-speed cameras are being used to capture images of welding beads at a rate of thousands of frames per second. This technology allows for a detailed analysis of the welding process, which can help identify areas for improvement and enhance quality control.

- Modified Atmosphere Welding: Modified atmosphere welding involves creating a controlled environment around the welding area to reduce the risk of oxidation, which can weaken the weld joint. This method is particularly useful for welding materials that are highly sensitive to oxidation, such as titanium.

- Plasma Arc Welding: Plasma arc welding is a high-precision process that uses a jet of ionized gas to create an intense heat source. This process can produce clean, efficient welds with minimal distortion or deformation, making it ideal for welding thin materials.

Conclusion

Understanding the basics of welding beads is essential for any aspiring welder. With proper technique and practice, you can create strong, durable joints and achieve the desired results with your welds. We hope this comprehensive guide has provided you with the necessary information to get started with welding beads.

FAQs

What is a stringer bead in welding?

- A stringer bead is a type of welding technique used to make a straight and narrow weld along a joint.

- It involves running a single pass of welding bead along the length of the joint.

- The resulting weld is often neat and uniform, but may not be as strong as other types of welds.

- The stringer bead technique is commonly used in welding thin materials or for filling small gaps.

- It is important to maintain consistent speed and angle while performing a stringer bead to ensure a quality weld.

What is a bead in welding?

- In welding, a bead is a term used to describe the material that is melted and deposited by the welding process.

- It refers to the visible line or raised area left on the surface of the metal after the welding is complete.

- The size, shape, and appearance of the bead can vary depending on the type of welding process and the skill of the welder.

- A properly formed bead is important for creating a strong and durable weld that can withstand the forces it will be subjected to.

- Welders must pay attention to the formation of the bead and make adjustments to their technique as necessary to ensure a quality weld.

James is a welding expert, accomplished author, and trusted guide with over 8 years of experience in the industry. With his in-depth knowledge and engaging writing style, James has become a true authority in the field, offering readers and clients invaluable expertise and insights to take their welding skills to new heights.

by James | May 6, 2023 | Welding

Heliarc welding, also known as Tungsten Inert Gas (TIG) welding, is a welding process that uses a non-consumable tungsten electrode to create an electric arc that melts and joins two pieces of metal together. This process produces a high-quality weld with minimal spatter and distortion, making it an ideal choice for applications where aesthetics and precision are important. Heliarc welding is commonly used in the aerospace, automotive, and manufacturing industries, where precision and quality are essential.

It is also used in the fabrication of stainless steel, aluminum, and other exotic metals that require a high degree of precision and control. The heliarc welding process involves feeding a tungsten electrode through a torch and into the workpiece. The tungsten electrode is non-consumable, meaning it does not melt and is not used as filler material. Instead, a separate filler material, often a wire made from the same material as the workpiece, is used to create the weld. Also, know what is arc welding and its benefits.

Advantages, Disadvantages and Applications of Helirac Welding

During the welding process, the tungsten electrode is held a short distance away from the workpiece, and an electric arc is struck between the electrode and the workpiece. The arc generates intense heat, melting the metal and creating a pool of molten metal. The filler material is then fed into the molten pool, creating a bond between the two pieces of metal.

The heliarc welding process requires a high degree of skill and precision, as the welder must maintain a consistent distance between the tungsten electrode and the workpiece while also controlling the flow of filler material. This process is typically performed using a heli arc welder, which is a specialized welding machine designed specifically for heliarc welding.

A heli arc welder is similar in appearance to a traditional arc welder, but it is equipped with additional features to facilitate the heli arc welding process. These features include a high-frequency generator, which helps to create and maintain the arc, as well as a foot pedal that allows the welder to control the amperage of the weld. One of the advantages of heli arc welding is that it produces a very clean and precise weld, with minimal spatter and distortion.

This makes it ideal for applications where aesthetics and precision are important, such as in the aerospace and automotive industries. Another advantage of heli arc welding is that it can be used to weld a wide variety of materials, including stainless steel, aluminum, and other exotic metals. This versatility makes it a popular choice in the manufacturing industry, where a wide range of materials may need to be welded together.

However, heli arc welding also has some disadvantages. It is a slower process than other types of welding, such as MIG welding, which can make it less efficient for high-volume production. Additionally, it requires a higher degree of skill and training than other types of welding, which can make it more expensive to implement. Despite these challenges, heli arc welding remains a popular choice for many applications due to its precision, versatility, and high-quality results.

With the right equipment and training, a skilled heli arc welder can produce high-quality welds that meet the most demanding standards of the aerospace, automotive, and manufacturing industries. However, the heliarc welding machine also supplies an inert gas, typically argon, to protect the weld area from atmospheric contamination. Heliarc welding machines come in various sizes and configurations, ranging from small, portable units to larger, industrial-grade machines. These machines offer precise control and produce high-quality welds, making them popular in a wide range of industries.

Importance of Heliarc Welding in Industries

Heliarc welding is widely used in various industries due to its versatility and ability to produce high-quality welds. The process is commonly used in the aerospace industry to weld aircraft components, such as engine parts, landing gear, and fuel tanks. The process is also used in the automotive industry to weld exhaust systems, suspension components, and body panels.

The process is also used in the construction industry to weld structural steel, aluminum, and stainless steel. Heliarc welding is commonly used to weld handrails, stairs, and other architectural features. The process is also used in the food and beverage industry to weld stainless steel tanks and piping.

Heliarc welding is an important process in various industries due to its ability to produce high-quality welds. The process is widely used in industries that require high-quality welds, such as the aerospace and automotive industries. The process is also used in industries that require the welding of thin materials, such as aluminum and stainless steel.

The process is also important in industries that require the welding of dissimilar metals, such as steel and aluminum. Heliarc welding is commonly used to weld dissimilar metals due to its ability to produce high-quality welds with minimal distortion.

Heliarc welding is also important in industries that require the welding of materials that are sensitive to atmospheric contamination. The process uses an inert gas to protect the weld area from atmospheric contamination, which is important in industries that require high-quality welds, such as the food and beverage industry.

What is a Heliarc Welding Machine

A heliarc welding machine, also known as a TIG welding machine, is a device used to create a high-temperature arc that melts and fuses metal together. The machine consists of a power source, a control panel, a welding torch, and a gas supply. The power source provides the electrical energy needed to create the arc, while the control panel allows the user to adjust the welding parameters, such as the amperage and voltage. The welding torch is used to direct the arc onto the workpiece, and the gas supply provides a shield of inert gas, usually argon, around the weld to prevent contamination.

How Does a Heliarc Welding Machine Work

The heliarc welding machine works by creating a high-temperature arc between a non-consumable tungsten electrode and the workpiece. The tungsten electrode is held in the welding torch and is used to create the arc. The arc creates a heat source that melts the metal of the workpiece, and as the torch is moved along the joint, the molten metal solidifies, fusing the two pieces of metal together. The gas supply is used to provide a shield of inert gas, usually argon, around the weld to prevent contamination from the air. The gas is directed out of the welding torch and creates a protective atmosphere around the arc and the weld pool. This helps to prevent oxidation and other types of contamination that can weaken the weld.

What is Heliarc Welding Used For

Heliarc welding is commonly used in applications where quality and precision are critical. It is often used in the aerospace and automotive industries, as well as in the fabrication of complex metal structures, such as bridges, ships, and buildings. The precision and control offered by heliarc welding make it an ideal choice for welding thin or delicate materials, such as aluminum, stainless steel, and titanium. Heliarc welding is also commonly used in the repair of machinery and equipment, as it can be used to weld a wide range of materials, including dissimilar metals. It is often used in the repair of engine components, such as cylinder heads, as well as in the repair of hydraulic and pneumatic systems.

Positive aspects of Heliarc Welding:

There are several advantages to using heliarc welding over other welding methods. These include:

- Precision: Heliarc welding allows for precise control over the welding process, making it ideal for welding thin or delicate materials.

- Quality: Heliarc welding produces high-quality, strong welds that are free from defects, such as porosity or inclusions.

- Versatility: Heliarc welding can be used to weld a wide range of materials, including dissimilar metals.

- Cleanliness: Heliarc welding produces very little smoke or fumes, making it a clean welding process.

- Aesthetics: Heliarc welding produces a clean, attractive weld bead that requires little to no post-weld cleanup. Control: The precise control offered by heliarc welding makes it possible to create complex welds with minimal distortion or warping.

- Heat Input: Heliarc welding produces a low heat input, which means that the heat-affected zone (HAZ) is small. This reduces the risk of distortion and warping in the workpiece.

- Weld Quality: Heliarc welding produces high-quality welds that are free from defects, such as porosity or inclusions. This makes it ideal for welding critical components, such as those found in the aerospace and medical industries.

- Weld Appearance: Heliarc welding produces a clean, attractive weld bead that is uniform in appearance. This is important in applications where aesthetics are important, such as in the production of high-end furniture or architectural components.

- Tungsten Electrode: The tungsten electrode used in heliarc welding is non-consumable, which means that it does not need to be replaced as often as other types of welding electrodes. This can result in lower welding costs and less downtime for electrode changes.

- Welding Speed: Heliarc welding can be performed at a relatively high welding speed, which means that large areas can be welded quickly and efficiently.

Welding Safety: Protect Yourself from Potential Hazards

Heliarc welding, also known as Gas Tungsten Arc Welding (GTAW), is a highly precise and versatile welding technique that is commonly used in many industries, such as aerospace, automotive, and manufacturing. Despite its many benefits, heliarc welding poses several safety hazards that should be taken seriously by anyone engaging in this practice. In this article, we’ll explore some of the key safety considerations that should be taken into account when performing heliarc welding using a heliarc welding machine.

First and foremost, proper ventilation is crucial when welding with a heliarc welder. This is because the welding process produces hazardous fumes and gases that can be harmful if inhaled. Exposure to these fumes can cause a range of health problems, including respiratory issues, dizziness, nausea, and headaches. To prevent this, it’s important to ensure that the welding area is well-ventilated. This can be achieved through the use of local exhaust ventilation, which draws the fumes away from the welder’s breathing zone, or through the use of general ventilation systems, such as fans or air purifiers.

In addition to proper ventilation, personal protective equipment (PPE) is also essential when performing heliarc welding using a heliarc welding machine. The PPE that should be worn during welding includes a welding helmet with a filter lens, safety glasses or goggles, a welding jacket or apron, welding gloves, and leather shoes or boots. The welding helmet should be fitted with a filter lens that is appropriate for the welding process and the type of metal being welded.

The filter lens protects the heliarc welder’s eyes from the intense light produced during welding, while the safety glasses or goggles protect the eyes from flying debris or spatter. The welding jacket or apron and gloves protect the heliarc welder’s skin from burns, sparks, and hot metal, while the leather shoes or boots protect the feet from falling objects and hot surfaces. Another important safety consideration when performing heliarc welding using a heliarc welding machine is the safe handling of welding equipment. This includes the welding machine, gas cylinder, and tungsten electrode holder.

Conclusion

Heliarc welding, also known as Tungsten Inert Gas (TIG) welding, is a highly precise and versatile welding process that produces high-quality welds with minimal spatter and distortion. This makes it an ideal choice for applications where precision and aesthetics are important, such as in the aerospace, automotive, and manufacturing industries.

The process requires a high degree of skill and control, as the welder must maintain consistent distance between the tungsten electrode and the workpiece, while also controlling the flow of filler material. However, with proper safety precautions and training, heliarc welding can be a safe and efficient welding process for a variety of materials. As technology continues to advance, it’s likely that heliarc welding will remain an important part of the welding industry for years to come.

James is a welding expert, accomplished author, and trusted guide with over 8 years of experience in the industry. With his in-depth knowledge and engaging writing style, James has become a true authority in the field, offering readers and clients invaluable expertise and insights to take their welding skills to new heights.

by James | May 1, 2023 | Product Reviews

In the world of welding, finding the best 110V MIG welder can be challenging due to the various models available. However, this article reviews four of the best 110V MIG welders available on the market, each with its own unique features and capabilities. Whether you are a beginner or a professional welder, you will find a suitable option for your welding needs.

The article takes an in-depth look at the Hobart Handler 140 Flux-Cored/MIG Welder, Forney Easy Weld 261 MIG Welder, and many other best 110V MIG welders, highlighting the pros and cons of each machine. We have also covered the best 110V stick welders for readers. Hope, here you will get an excellent quality mig welding machine that will meet all your needs.

Hobart Handler 140 Flux-Cored/MIG Welder

The Hobart Handler 140 MIG Welder is among the best 110V MIG welders. It’s a versatile and reliable machine that offers a wide range of features and specifications suitable for various welding projects. With its 5-position voltage control selector, the machine provides a smooth and stable arc at all welding thicknesses, allowing for high-quality welds. This feature is particularly useful when welding materials of varying thicknesses, as it permits the user to adjust the machine’s output accordingly, making it ideal for both beginners and professionals.

The machine’s capability of welding materials ranging from 24 gauge up to 1/4 inch in mild steel makes it highly versatile. This weldable range includes steel, stainless steel, and aluminum, allowing for a wide range of applications. Additionally, the machine supports MIG (GMAW) and flux-cored (FCAW) welding processes, allowing users to choose the best process for their specific needs.

One of the significant advantages of the Hobart Handler 140 MIG Welder is its ability to operate off 115V standard household current, making it a highly convenient machine to use in various settings. Its wire feed speed range is 40-700 IPM, with 50-740 IPM at no load, allowing users to adjust the machine’s speed to match the specific material they are working with. The machine’s welding amperage range is 25-140 A, with a 20% duty cycle at 90 amps and 19V. These specifications make the Hobart Handler 140 MIG Welder a powerful and reliable machine that can handle a wide range of welding tasks.

In short, the Hobart Handler 140 MIG Welder is among the best 110V welders as it’s a reliable and highly capable welding machine suitable for a wide range of welding projects. It’s a convenient and easy-to-use machine that is ideal for beginners and professionals. Its powerful and versatile features make it a valuable addition to any welding workspace.

Pros & Cons

Pros- Perform well with both CO2 and other gases

- Capable of welding thick sheet metal and zinc

- Easy to use for hobbyists and beginner welders

- Provides name-brand quality at an affordable price

Cons- Inconsistent welds

- Only suitable to use in the USA

Forney Easy Weld 261 MIG Welder

Forney Easy Weld 261 is one of the best 110V MIG welders for entry-level. It is easy to use and perfect for DIY, maintenance, repair, metal fabrication, and hobbyist projects. Users can easily dial in the perfect weld with its infinite voltage and wire feed speed control. Its lightweight design at only 19 lbs. also allows for easy portability to any job site.

The Forney Easy Weld 261 is built to handle day-to-day ruggedness with its all-metal case and can handle 2 and 10-pound rolls of wire. The machine comes with a 12-month warranty. The machine’s dimensions are 16.75″ x 8.125″ x 12″, and it can weld up to 1/4 inch plate thickness, with a duty cycle of 30% at 90A.

While the Forney Easy Weld 261 only supports gasless/flux-core welding, it includes infinite voltage and wire feed speed control, making it a versatile tool for a variety of projects. For optimal performance, Forney recommends the use of contact tips, welding nozzles, diffusers, flux core MIG wire, anti-spatter spray, and nozzle gel. In short, all of these features make the Forney Easy Weld 261 one best 110-volt MIG welder choices for those seeking an affordable, powerful, and portable MIG machine.

Pros & Cons

Pros- Easy to use

- Durable for long-term use

- Quick and easy post-weld clean-up

- Comes with recommendations to enhance performance

Cons- Difficult to get the settings right

Weldpro Digital TIG 200 4.7

The Weldpro Digital TIG 200GD is another one of the best 110v mig welder options in this list. It’s a powerful 200 amp AC/DC TIG welder that offers advanced welding capabilities beyond just steel and aluminum. This digital designed TIG welder is equipped with full-function TIG welding features typically found on many higher-priced machines, making it an excellent choice for professionals looking for a versatile and reliable welding tool.

With features like start and end amps, upslope, downslope, fully adjustable pulse, AC balance, AC frequency, and 2T-4T options, the Weldpro Digital TIG 200GD provides exceptional control over the welding process. Additionally, the machine comes with an excellent professional design rocker-style foot pedal that eliminates the need for intermediate amperage control, allowing for a more streamlined and efficient welding experience.

The Weldpro Digital TIG 200GD also features a fully capable MMA stick welding function with a stinger included, making it a great all-around tool for various welding applications. And with the optional CK Worldwide Superflex cable and flex head number 17F torch with an independent trigger switch, users can further enhance their welding experience. Plus, the machine comes with a full 3-year warranty, giving users peace of mind knowing that they are investing in a high-quality, long-lasting welding tool.

Pros & Cons

Pros- 2-year warranty

- Excellent adjustable A/C duty cycle

- Provides about 8 hours of run time

- Maximum reliability during high amperage output

Cons- Difficulties in getting the machine to work correctly

Lotos MIG140 MIG Welder 4.6

Lotos MIG140 MIG Welder is added to the list of the best 110v mig welder due to its versatility and reliability in the welding machine. It can handle a variety of welding tasks with ease. The durable aluminum wire feeder provides stability during welding, resulting in better and more consistent welds. With a rated output of 140 amps, this MIG welder is capable of welding mild and stainless steel ranging from 24 gauge to 3/16 inch. It is also capable of welding other metal materials, such as aluminum, with a spool gun.

One of the standout features of the Lotos MIG140 MIG Welder is the 2T/4T switch, which allows for manual or semi-automatic welding. This feature is especially useful for long-time welding jobs, as it reduces fatigue and allows the user to release their finger while still maintaining control over the welder. Additionally, the customer can adjust the wire feeder speed and welding voltage more precisely with the help of two digital displayers, resulting in more accurate and consistent welds.

The machine can be easily connected to a standard 110/120v wall outlet, making it accessible and convenient for home-based welding projects. Lotos MIG140 MIG Welder has a 3-year limited warranty, including a 1-year new replacement warranty. Overall, Lotos MIG140 MIG Welder is one of the best 110 welders with versatile and reliable welding and is perfect for beginners and experienced welders.

Pros & Cons

Pros- Great welding performance for both MIG and Flux core.

- Affordable price

- Easy to operate

- Suitable for hobby projects and light welding tasks

Cons- Inconsistent wire feed rate

YESWELDER Digital MIG-205DS MIG Welder

The YESWELDER Digital MIG-205DS MIG Welder is a high-performance welding machine, therefore, it’s included in the list of the best 110v mig welder. It uses IGBT inverter technology to ensure reliable quality and stable performance. With a full 30-205Amp(max) and digital display, this welding machine is capable of handling a wide range of welding tasks.

Equipped with synergic control, the voltage and wire feeding speed of the MIG-205DS automatically change when adjusting the amperage or choosing different thicknesses. This feature makes it easy for beginners to use and achieve precise welding results.

The MIG-205DS is a versatile welding machine that is capable of true lift TIG welding (additional tig lift torch required, not included), stick welding, and gas MIG/gasless MIG welding. It also supports aluminum MIG welding with spool gun compatibility. The LBT150 spool gun reduces the distance that the wire needs to travel, providing better visibility for the moving wire (sold separately).

Safety is a top priority for YESWELDER, and the MIG-205DS is equipped with an automatic protection function for over-current, over-voltage, and over-heating. With its advanced features and reliable performance, the YESWELDER Digital MIG-205DS MIG Welder is an excellent choice for professional welders and DIY enthusiasts alike.

Pros & Cons

Pros- Longer cord

- Allows for aluminum welding

- The interface has more options available

- Converter included to take it from 220V to 110V

ARCCAPTAIN 130A MIG Welder

The ARCCAPTAIN 130A MIG Welder is another one of the best 110V MIG welder. It is perfect for beginners and experienced welders alike. With its synergic control feature, the recommended current and wire feeding speed are automatically matched based on the selected diameter of the welding wire, making it easier for beginners to learn how to weld and make small repairs around the house.

This 3-in-1 welder has three different welding modes including Flux Core Gasless MIG, Lift TIG, and MMA, which meet a variety of different welding requirements. With its adjustable current and 10-speed variable feed controls, you can achieve perfectly managed flux-cored welding of carbon steel, stainless, or even thicker steel. This makes it the best 110V MIG welder for home DIY projects, outdoor repairs, rusty metal, farm and road equipment, and maintenance and repairs.

Safety is a top priority for the ARCCAPTAIN 130A MIG Welder, and it comes with built-in over-current protection, over-load protection, overheating, and over-voltage function that extend the lifespan of the machine. Additionally, the machine is portable and compact, weighing only 11.79 pounds, and comes with a handle or shoulder strap for easy transport.

The company offers warm service and a 2-year warranty, as well as a 30-day money-back guarantee. Every single welder machine is thoroughly tested in authoritative laboratories to ensure it conforms to high standards before leaving the ARCCAPTAIN factory.

Pros & Cons

Pros- Advanced features

- Excellent adjustment options

- Suitable for DIY hobby use

- Produces smooth and easy-to-control weld bead

Cons- Not suitable for thin metal sheets or wire welding

Lincoln Electric K2185-1 Handy MIG Welder

The other best 110V MIG welder with a big name and qualities is Lincoln Electric K2185-1, Handy MIG Welder. It’s a compact and portable wire feed welder that is imported and user-friendly. It comes with 12.8” H x 8.8” W x 18” D dimensions and weighs only a few pounds. These qualities make it easy to transport and used for various light welding tasks. The welding machine is designed for welding up to 1/8 inch mild steel and can be powered by a 115V, 20A power supply. The power cord length is 6ft, which gives users some flexibility in where they can position the welder.

One of the safety features of this welder is the cold contactor, which keeps the welding wire electrically “cold” until the gun trigger is pressed. This safety feature ensures that the operator is protected from electric shocks and burns. This makes the Lincoln Electric K2185-1 Handy MIG Welder one of the best 110V MIG welder for beginners or hobbyists who are just starting out with welding.

The Lincoln Electric K2185-1 Handy MIG Welder is also suitable for home repair and hobby projects on light gauge mild steel found around most households. Users can weld mild steel from 24 gauge to 1/8″ thick with four voltage settings and continuous wire feed speed adjustment. However, it is important to note that shielding gas is sold separately and needs to be purchased separately. This might be an extra expense for some users.

Overall, the Lincoln Electric K2185-1 Handy MIG Welder is an affordable and user-friendly option for hobbyists and DIY enthusiasts who need a lightweight, portable and compact welding machine for light welding tasks. However, users must be aware of the additional cost of separately purchasing shielding gas.

Pros & Cons

Pros- Easy to use

- Easy transportation and storage

- cold contactor safety feature

- Compact, portable, and lightweight

- Ideal for home repair and hobby projects on light gauge mild steel

Cons- Settings can be tricky to figure out and require some trial and error

AZZUNO 200A MIG Welder

The AZZUNO 200A MIG Welder is included in the list of the best 110v mig welder because it’s a versatile welding machine that offers four different welding modes. It offers MMA, Lift TIG, flux MIG, and gas MIG modes. Its synergic control feature allows for automatic voltage and wire feeding speed adjustments based on the selected amperage or wire thickness, making it user-friendly even for beginners. With the option to choose between gas and gasless welding, this welder can handle 2 lb and 10 lb rolls of wire ranging from 0.8mm to 1.0mm, with a maximum welding thickness of 4.5mm.

In addition to its various welding modes, the AZZUNO 200A MIG Welder also supports Lift TIG and ARC welding. The TIG torch fits WP17V, although not included in the package, and is suitable for welding thin work-pieces such as stainless steel, alloy steel, and carbon steel up to 3mm thick. The ARC welding mode is compatible with rods E7018 and E6013.

Despite its power and versatility, the AZZUNO 200A MIG Welder is also designed with safety in mind. It can weld mild steel up to 4.0mm thick and is equipped with an overload and overheating system to ensure user safety. With its wide range of features and safety measures, this welding machine is the best 110v mig welder for the money and for anyone looking for a reliable and efficient welding solution.

Pros & Cons

Pros- Good fit and finish

- Suitable for beginners

- Easy setup and simple settings

- Affordable price point for a versatile MIG welder

VIVOHOME Flux Core Wire MIG 130 Welder

Looking for one of the best 110V MIG welding machines that deliver a professional finish for your home repair and hobby projects on light gauge steel? Look no further than the VIVOHOME MIG Welder 130. This welding machine is a great choice for those looking to prevent oxidation of the welded part, as it conveniently uses flux-cored wire to self-release metal inert gas while welding.

This versatile welding machine is particularly well-suited for mild steel and stainless steel projects. With its adjustable welding speed, you can manage flux-cored welding of thin steel, stainless or aluminum sheet metal, or even thicker steel. The VIVOHOME MIG Welder features 4x current flow settings and 10-speed variable feed controls, allowing you to adjust the current to your needs.

Not only is this welding machine efficient and powerful but it’s also designed to be portable. Its lightweight and compact design, complete with a comfortable hand grip, makes it easy to carry wherever you need to go. Weighing in at only 34.6 lbs., the VIVOHOME MIG Welder can be effortlessly taken to your next project location. So why wait? Get your VIVOHOME MIG Welder today and start tackling all your welding projects with ease.

Pros & Cons

Pros- Easy to transport

- Straightforward to set up

- Great value for money

- Compact and lightweight design

Cons- Switches and knobs affect voltage and wire feed speed

Conclusion

In conclusion, choosing the best 110V MIG welder depends on specific needs and requirements. The Hobart Handler 140 MIG Welder is an excellent choice for professionals and beginners alike with its versatile features and reliable performance. The Forney Easy Weld 261 MIG Welder is perfect for entry-level welders and DIY projects with its affordability, portability, and ease of use.

The Weldpro Digital TIG 200GD offers advanced welding capabilities beyond steel and aluminum, making it a perfect choice for professionals seeking a versatile, reliable, and high-quality welding tool. Each machine has its advantages and disadvantages, and users must consider their needs before making the final decision.

Read More: Best MIG Welder under $1000

James is a welding expert, accomplished author, and trusted guide with over 8 years of experience in the industry. With his in-depth knowledge and engaging writing style, James has become a true authority in the field, offering readers and clients invaluable expertise and insights to take their welding skills to new heights.

by James | Mar 19, 2023 | Product Reviews

Welding rusty and unclean metal surfaces can be a challenge for any welder. However, with the best 110v stick welder, it is now possible to weld even the most challenging surfaces without the need for thorough cleaning. Stick welding is one of the oldest forms of modern welding and has been the go-to solution for welders when it comes to maintenance and general repair jobs. Also read how many amps does a welder use.

Unlike MIG, stick welding does not require shielding gas, and its flux element on the electrode enables it to weld both indoors and outdoors. Additionally, stick welding can bond a wide range of metals, including iron, steel, thick aluminum, copper alloys, and nickel, making it a versatile choice for welders. Choosing the best beginner stick welder can be a daunting task, especially if you’re new to welding. It is crucial to choose a machine that is easy to use, reliable, and delivers optimal performance for your welding needs.

A 110v stick welder is an excellent choice for beginners, as it is designed for low amps and offers a more forgiving welding process compared to other welding machines. Additionally, a 110v stick welder is more affordable than its 220v counterpart and is suitable for farm work or home maintenance and repair tasks. It is best for a welder to know how hot is an arc welder. In this article, we will explore some of the best 110v stick welder machines that are reliable, versatile, and easy for beginners to learn.

Forney Easy Weld 298 Arc Welder 100ST

As a welder, I was looking for a reliable and affordable stick welder that could handle light-duty welding tasks around my home. After doing some research, I came across the Forney Easy Weld 298 Arc Welder, which seemed to tick all the boxes. And I must say, I have been thoroughly impressed with this machine’s performance.

One of the things that I really like about this welder is its inverter power system, which allows it to convert AC to DC and save energy. This means that even if there’s an electrical surge, the flow of energy on the machine remains stable, which is a great feature for a beginner like me who’s still learning the ropes. Another highlight of the Forney Easy Weld 298 is its TIG welding capability.

Although you need to buy the TIG torch separately, it’s still a great option to have as it allows you to weld even thin metal sheets. However, I have been using this machine mainly as a stick welder, and it has been performing admirably well. This machine can handle metal rods up to 1/8 inch in diameter and welds 16 gauge up to 5/16 inch thick metals, making it a versatile option for light-duty welding tasks around the home. It’s also portable and compact, weighing only about 13 lbs., which makes it easy to move around and store.

The Forney Easy Weld 298 comes with an 8′ electrode holder and an 8′ ground clamp, which is a great addition to have. However, I did end up buying the Steel Ground Clamp, 300 AMP, Medium Duty Electrode Holder, 200 AMP, Straight Head Chipping Hammer, Argon/CO2 Flow Meter, Ground Cable & Clamp, 150 AMP, 15’, and Electrode Holder w/ Cable, 150 AMP, 15’ recommended accessories, which have made my welding experience even better.

Overall, I’m extremely satisfied with the Forney Easy Weld 298 Arc Welder, and I would highly recommend it to any beginner or hobbyist who’s looking for an affordable and reliable stick welder that can handle light-duty welding tasks.

Pros & Cons

Pros- Simple and user-friendly operation

- No need for a dedicated breaker

- Lightweight and portable design

- Compatible with standard 110v household outlets

Cons- Comes with only 8-foot leads

- Not suitable for welding beyond 5/16-inch steel

2020 PowerArc 140ST 40 Amp Arc Stick Lift Start TIG Welder

As a welding enthusiast, I am always on the lookout for the best stick welder that I can use at home or at work. The 2020 PowerArc 140ST 40 Amp Arc Stick Lift Start TIG Welder caught my attention because of its compact and portable design, complete with a carrying case that makes it easy to transport. Plus, it has everything I need for both stick welding and lifts TIG welding.

One of the things I love about this welder is its auto-adaptive hot start system, which makes it easy to start and provides maximum flexibility and performance. I also appreciate the fact that it has a dual-voltage design, which means I can use it anywhere, whether at home or at work. However, if I want to use its TIG capability, I need to purchase its gas regulator separately.

This welder is capable of providing a stable and smooth DC arc at a maximum of 140 amps with a 35% duty cycle at rated amps. I found the digital display to be very helpful for easy current settings, and some reviews have even stated that it can weld up to 1/2” bar stock to 1-inch thick plates using 3/32 filler rods at multiple passes on 120 amps settings. That’s quite impressive for a compact stick welder!

While this welder may be a bit expensive for beginners looking for a cheap stick welder, its capacity of up to 140 amps and TIG capability make it a great investment for those who plan on using it at work or for general repairs for tools and equipment. Overall, I highly recommend the 2020 PowerArc 140ST 40 Amp Arc Stick Lift Start TIG Welder to anyone looking for a reliable and high-performance welder that is easy to use and transport.

Pros & Cons

Pros- 5-years warranty

- Features lift TIG function

- Front digital display

- Compact and includes a carrying case

- Auto-adaptive hot start for easy start-up

Cons- There comes issues with digital reading

Miller Maxstar 161 S Series Stick Welder

The Miller Maxstar 161 S Series Stick Welder is a top-of-the-line machine designed for professionals who demand high-quality performance and durability. Its industrial build quality and ability to accommodate 6010 rods set it apart from lightweight inverter-type welders that often struggle with this task. In addition, the machine is CSA certified, meaning it meets the standards required for government jobs.

Despite its exceptional performance, some users have reported issues with the digital controls wearing out or breaking under heavy use. However, this is a minor concern for DIY enthusiasts who may not use the machine as frequently as professionals.

One of the standout features of the Miller Maxstar 161 S Series Stick Welder is its ability to deliver up to 90 amps output on 110 volts, providing smooth and precise welding results. The anti-sticking feature prevents electrode sticking, while the power-cutting mechanism ensures user safety. Furthermore, the power factor correction feature allows the machine to maintain consistent performance when switching between 110 volts and 240 volts, making it a versatile and reliable option for any welding project.

Pros & Cons

Pros- It has only 13 pounds weigh

- When stuck, anti-sticking cuts power

- Lowers voltage when not working

Cons- Digital controls are of poor quality

Final Words

These 110v stick welders are an excellent choice for DIY enthusiasts and professionals who need a compact, portable, and reliable welding machine. There are many different models on the market, each with its own set of features and advantages. However, after careful consideration of various factors such as build quality, performance, ease of use, and affordability, Forney Easy Weld 298 Arc Welder stands out as one of the best options for professional welders and repair workers.

James is a welding expert, accomplished author, and trusted guide with over 8 years of experience in the industry. With his in-depth knowledge and engaging writing style, James has become a true authority in the field, offering readers and clients invaluable expertise and insights to take their welding skills to new heights.

by James | Mar 6, 2023 | Product Reviews

Plasma cutters have revolutionized the metalworking industry by providing fast, precise, and efficient cutting capabilities for a wide range of materials. However, finding the right plasma cutter that fits your budget can be a daunting task. With so many options available on the market, it can be challenging to sift through the various features and models to find the best one for your needs. That’s where we come in!

In this article, we’ll be exploring the best plasma cutters under $1000. We understand that not everyone can afford a high-end plasma cutter, but that doesn’t mean you have to compromise on quality. There are plenty of affordable options available that can provide excellent performance, durability, and efficiency. We’ll be discussing the top plasma cutters under $1000, their features, and what sets them apart from other models. We have also covered the best plasma-cutting machines under $500.

We’ll also provide tips on what to consider when purchasing a plasma cutter, such as amperage, cutting thickness, portability, and ease of use. Whether you’re a DIY enthusiast, small business owner, or a professional metalworker, our list of the best plasma cutters under $1000 has got you covered. With the right plasma cutter, you can cut through a variety of materials quickly and easily, giving you the ability to take on any project with confidence. So, let’s dive into the world of plasma cutters and find the one that fits your budget and needs!

The PRIMEWELD CUT60 Plasma Cutter is a modern and versatile machine that offers exceptional cutting capabilities and ease of use. One of the standout features of this plasma cutter is its blow-back start technology and pilot arc, which allows for continuous cutting of expanded, rusted, and painted metals. This feature makes it ideal for a range of cutting applications, from industrial and construction work to home and hobby use.

Another impressive feature of the PRIMEWELD CUT60 is its 60% duty cycle at 60amps and dual-voltage 110V/220V with an adapter. This makes it a highly versatile and efficient machine that can handle a range of cutting tasks. Plus, its small and lightweight design makes it highly portable, allowing you to take it wherever it’s needed. Included with the PRIMEWELD CUT60 is a PT60 blowback cutting torch with a Euro Central Connection, which provides premium control over your cutting projects.

The torch is designed to produce top-quality cuts in a range of metal materials, including stainless steel, alloy steel, mild steel, copper, and aluminum. What really sets the PRIMEWELD CUT60 apart is the company’s commitment to top-notch customer service and its 3-year warranty. Their USA-based parts and customer service team is available 7 days per week to assist with any questions or concerns. This level of customer support is a valuable asset, especially for those who are new to plasma cutting or may need assistance with troubleshooting or repairs.

Overall, the PRIMEWELD CUT60 Plasma Cutter is a highly recommended machine for those who are looking for a reliable and efficient plasma cutter that offers exceptional cutting capabilities, versatility, and ease of use. Its continuous pilot arc, blow-back start technology, and dual-voltage capabilities make it a valuable addition to any workshop, whether for industrial or hobby use. And with its 3-year warranty and top-notch customer service, you can be confident that you’re making a smart investment in a quality machine.

Pros & Cons

Pros- Continous Pilot Arc

- PT60 Torch Included

- Comes with a 3-year warranty

- Blow-back start technology

- Small and Lightweight Plasma Cutter

Cons- Need 50A circuit for 240V operation

- Better if comes with a large air compressor

Lotos LTPDC2000D Plasma Cutter

LotosLTPDC2000D is a versatile 3-in-1 combo welding machine that functions as a 50A plasma cutter, a 200A TIG welder, and a 200A stick/MMA welder. It operates on dual voltage, 220V or 110V, and has a non-touch pilot arc technology that efficiently cuts through rough, painted, and rusty surfaces while producing minimal slag. The plasma cutter can achieve a clean cut thickness of up to 1/2″ and a max severance thickness of 3/4″.

The TIG and stick/MMA welders have a current output range of 10-200A @ 220V and 10-150A @ 110V. The machine employs the latest technology, such as IGBT/MOSFET-based high-frequency inverter technology and pulse width modulation, to deliver consistent and precise current to the cutting surface, resulting in smooth, clean cuts on a wide range of materials, including stainless steel, alloy steel, brass, aluminum, and other conductive materials.

The machine is designed for both professional and DIY users and comes with a 30-day money-back guarantee and a 1-year new replacement warranty, with an optional 3-year limited warranty available. Lotos Technology, headquartered in Santa Clara, California, USA, has been a reputable source of affordable industrial and consumer-based portable plasma cutters and welders since 2007.

Pros & Cons

Pros- Multi-purpose machine

- Non-touch pilot arc

- Comes with a 13-foot torch lead

- Compact design plasma cutter

- Includes air filter regulator

Cons- Old style design

- Only six-foot ground lead

Reboot RBC-5000D 110/220V Plasma Cutter

The Reboot RBC-5000D 110/220V Plasma Cutter is a versatile and reliable cutting machine that is suitable for use with a variety of materials, including stainless steel, alloy steel, mild steel, copper, cast iron, and chrome. With its automatic dual voltage feature, it can be easily converted from 110V to 220V, making it perfect for both home and industrial use.

One of the standout features of the Reboot RBC-5000D Plasma Cutter is its duty cycle. With a 60% duty cycle at 50A and 100% duty cycle at 40A, this machine is capable of handling heavy cutting tasks without overheating or losing power. It can cleanly cut through carbon steel up to 1/2″ (12mm) thick on 220V, and up to 3/8″ (9mm) thick on 110V.

The cutting machine is also very easy to operate. It comes with a 13ft PT31 welding torch and two torch consumables, as well as a gas regulator with a 6.5ft gas hose. The conversion line makes it easy to switch between 110V and 220V, and the air pressure of 60-70PSI ensures a smooth and efficient cutting process. The plasma cutter also has a built-in protection mechanism that shuts down the machine when it gets overheated or over-current, preventing any damage.

The Reboot RBC-5000D Plasma Cutter is compact and lightweight, weighing only 21.3 pounds. It is also very easy to transport, thanks to its convenient carrying handle. The LCD display provides clear and accurate readings of the current and voltage, making it easy to adjust the settings as needed. One minor drawback of this plasma cutter is that it can only handle mild steel up to 4/5″ in thickness, which may not be sufficient for some industrial applications.

However, for most home and DIY projects, this should not be an issue. Overall, the Reboot RBC-5000D 110/220V Plasma Cutter is a reliable and efficient cutting machine that offers excellent value for money. With its high-duty cycle, easy operation, and versatile cutting capabilities, it is a great investment for anyone in need of a reliable cutting tool.

Pros & Cons

Pros- It has affordable consumables

- Comes with an air filter regulator

- 110/120 & 220/240-volt input

- Lightweight with compact design

Cons- Short length lead

- Not best for industrial use

Lotos LTP8000 80 A Plasma Cutter

The Lotos LTP8000 80 A Plasma Cutter is an exceptional machine that delivers superior cutting performance with minimal heat input and distortion of metal. With a maximum clean cut thickness of 1 inch and a maximum severance thickness of 1 1/2 inches, this plasma cutter is suitable for cutting stainless steel, alloy steel, mild steel, copper, and aluminum, making it an ideal choice for factory maintenance, fabrication work, farm work, and auto body repairs.

The non-touch pilot arc feature is a standout feature of this plasma cutter. It efficiently cuts through rough, painted, and rusty surfaces and produces minimal slag. With pilot arc technology, you can cut without touching the tip to the metal, ensuring better cutting quality and longer consumable life. The Lotos LTP8000 80 A Plasma Cutter has been designed to incorporate the latest high-frequency inverter technology using V-MOSFETs and PWM. That helps to deliver a more constant, concentrated, and precise current to the cutting surface. The result is smooth, clean, and uniform cuts on a wide range of surfaces.

The advanced cooling system with the PAPST advanced German cooling system ensures a duty cycle of 60% at maximum output, allowing for extended use without overheating. The machine can perform at 60% duty cycle @70 A output & 100% duty cycle at 50 A output, making it a heavy-duty machine that is perfect for professional operators and DIY users. The machine is easy to use, with a pre-installed NPT 1/4” industry type D plug and air filter regulator that allows for quick connection to your air compressor.

The whole machine can be set up quickly within 1 minute, and the 2T/4T enabled feature allows for long-time cuts without fatigue. Overall, the Lotos LTP8000 80 A Plasma Cutter is an excellent machine that offers superior cutting performance, durability, and ease of use. With a 30-day refund policy and a 3-year limited warranty, you can buy with confidence, knowing that Lotos Technology offers excellent customer care and support.

Pros & Cons

Pros- It can cuts up to 1.5 inches

- Long lead for mobility around work

- 4T trigger which is best for long cuts

- Cuts through rust and other crud

Cons- Not for CNC work

- Power cord start getting hot

Hobart 500564 Airforce 12ci Plasma Cutter

As a professional welder, I am always on the lookout for tools that can improve my productivity and quality of work. Recently, I had the opportunity to test out the Hobart 500564 Airforce 12ci Plasma Cutter, and I must say I am impressed with its performance. The first thing that caught my attention was the built-in air compressor. This feature eliminates the need for an external compressor, making the 12ci extremely portable and easy to use.

I also appreciated the pre-set pressure, which made it simple to start cutting right out of the box. All I had to do was pull the trigger, and I was off to the races. When it comes to cutting, the Airforce 12ci is top-notch. It cuts faster than oxy-fuel, with a smaller heat-affected zone, resulting in less warping. The precise cut and thinner kerf also meant that there was less slag to clean up after cutting.

Overall, I found that the 12ci offered more precise and efficient cuts than other cutters I have used in the past. The 12ci is also incredibly lightweight, weighing in at just 27 pounds. This makes it easy to move around my workspace, which is essential for me as I often work on large projects that require me to move around frequently. In terms of size, the 12ci is a 12-inch cutter, which is perfect for most of the projects I work on.

It has a sturdy steel construction and a sleek brown finish, which adds to its aesthetic appeal. Hobart 500564 Airforce 12ci Plasma Cutter is an excellent investment for any professional welder or DIY enthusiast. Its built-in air compressor, pre-set pressure, and lightweight design make it easy to use and transport, while its cutting capabilities are top-notch. I highly recommend this plasma cutter to anyone looking to up their welding game.

Pros & Cons

Pros- Pilot arc start

- Quality torch

- Ventilator on demand

- Hobart airforce 12ci is simple to use

Cons- Not enough power

- Poor design plasma cutter

- Not suitable for industrial use

Buying Guide for Plasma Cutters Under $1000

Plasma cutters are versatile and powerful tools that can cut through metal quickly and precisely. They use an electric arc to ionize the gas and create plasma, which then melts the metal and cuts it with ease. In this buying guide, we will explore the best plasma cutters under $1000, and provide you with all the necessary information to make an informed decision when buying one.

Cutting Capacity

The cutting capacity of a plasma cutter determines the thickness of the metal it can cut. Make sure to consider the maximum cutting capacity of the plasma cutter you are interested in to ensure it can handle the type of metal you will be cutting.

Duty Cycle

The duty cycle refers to the amount of time a plasma cutter can operate without overheating. It is usually expressed as a percentage, such as 60% duty cycle at 50 amps. The higher the percentage, the longer the plasma cutter can operate continuously. Make sure to choose a plasma cutter with a duty cycle that meets your needs.

Portability

If you plan on using your plasma cutter in multiple locations, portability is an important factor to consider. Look for a lightweight and compact plasma cutter that comes with a carrying case or handle for easy transport.

Power Input

The power input of a plasma cutter determines how much power it needs to operate. Plasma cutters can be powered by either 110V or 220V outlets, and some models can even be used with both. Make sure to choose a plasma cutter that matches the power input of your work area.

Torch Type

The type of torch used by a plasma cutter affects its performance and cutting ability. There are two types of torches: handheld and machine-mounted. Handheld torches are more versatile, but machine-mounted torches provide better precision and stability.

Price

While budget is an important factor, it is not the only factor to consider when buying a plasma cutter. Look for a model that provides a good balance between price and features.

Warranty

Plasma cutters can be a significant investment, so it is important to choose a model with a warranty that provides adequate protection. Look for models with at least a one-year warranty, and consider purchasing an extended warranty for added peace of mind.

Final Words

Choosing the best plasma cutter under $1000 requires careful consideration of several factors, including cutting capacity, duty cycle, portability, power input, torch type, price, and warranty. By keeping these factors in mind, you can find a plasma cutter that meets your needs and provides the performance you require. If you have not chosen yet, my advice is to go with Primeweld Cut60 Non-Touch Pilot Arc Plasma Cutter. It is one of the best plasma cutters available in the market.

James is a welding expert, accomplished author, and trusted guide with over 8 years of experience in the industry. With his in-depth knowledge and engaging writing style, James has become a true authority in the field, offering readers and clients invaluable expertise and insights to take their welding skills to new heights.