by James | Jun 29, 2024 | Buying Guide

In the realm of welding equipment, choosing the right helmet can significantly impact both comfort and productivity. One crucial consideration is the power source for the auto-darkening feature, which plays a vital role in ensuring safety and efficiency during welding tasks. This article delves into the comparison between solar powered and battery powered welding helmets, exploring their features, benefits, and potential drawbacks to help you make an informed decision.o

Solar Powered Welding Helmets

Solar powered welding helmets harness energy from the sun to power their auto-darkening lenses. Here’s a detailed look at their key characteristics:

Features:

1. Energy Efficiency: Solar helmets are eco-friendly and cost-effective since they rely on renewable solar energy rather than disposable batteries.

2. Continuous Operation: They are designed to work continuously as long as there is sufficient ambient light, making them ideal for outdoor and well-lit indoor environments.

3. Longevity: Typically, solar panels and associated components are durable and have a long lifespan, reducing the need for frequent replacements.

Benefits:

Cost Savings: Over time, solar powered helmets save money on battery replacements.

Reliability: They ensure consistent operation during extended welding sessions without interruption due to battery depletion.

Environmental Friendliness: Solar power reduces the environmental impact associated with disposable batteries.

Drawbacks:

Low-Light Conditions: In poorly lit environments or during night welding, solar powered helmets may not function optimally without sufficient sunlight.

Battery Powered Welding Helmets

Battery powered welding helmets rely on replaceable or rechargeable batteries to operate their auto-darkening function. Here are their notable characteristics.

Features:

1. Portability: Battery powered helmets are generally lighter in weight and more portable than their solar counterparts.

2. Versatility: They can operate in any lighting condition, making them suitable for both indoor and outdoor welding projects.

3. Immediate Availability: Batteries provide instant power, ensuring immediate functionality without relying on external light sources.

Benefits:

They are suitable for all welding environments, including low-light or night-time conditions.

Convenience: Batteries can be easily replaced or recharged, ensuring minimal downtime.

Drawbacks:

Operating Costs: Continuous use may require frequent battery replacements or recharges, which can add to operational costs over time.

Environmental Impact: Disposable batteries contribute to electronic waste unless properly recycled.

Choosing the Right Helmet for You

When deciding between solar powered and battery powered welding helmets, consider the following factors:

Work Environment: Assess whether you predominantly work indoors or outdoors, and the lighting conditions you typically encounter.

Budget: Factor in initial costs versus long-term savings on maintenance and replacement.

Preference: Determine your preference for eco-friendly solar power or the convenience of battery operation.

Conclusion:

Both solar powered and battery powered welding helmets offer unique advantages tailored to different welding environments and user preferences. Solar helmets excel in sustainability and long-term cost savings, while battery helmets provide flexibility and immediate functionality in any lighting condition.

Ultimately, the choice depends on your specific needs, budget considerations, and environmental priorities. By understanding the differences outlined in this comparison, you can confidently select the welding helmet that best suits your requirements for safety, comfort, and efficiency.

James is a welding expert, accomplished author, and trusted guide with over 8 years of experience in the industry. With his in-depth knowledge and engaging writing style, James has become a true authority in the field, offering readers and clients invaluable expertise and insights to take their welding skills to new heights.

by James | Jun 18, 2024 | Buying Guide

Welding is a skilled trade that plays a crucial role in various industries, from construction and manufacturing to automotive and shipbuilding. If you’re considering a career in welding, you might be wondering, “Is welding hard to learn?” This comprehensive guide will explore the challenges and rewards of learning to weld, what it takes to become proficient, and tips for mastering this valuable skill.

Understanding Welding

Welding involves joining materials, usually metals, by melting and fusing them together. This process requires precision, technical knowledge, and manual dexterity. There are several welding techniques, including:

- MIG (Metal Inert Gas) Welding: Uses a continuous wire feed as an electrode and a shielding gas to protect the weld.

- TIG (Tungsten Inert Gas) Welding: Uses a non-consumable tungsten electrode and requires a separate filler material.

- Stick Welding: Uses a consumable electrode coated in flux to lay the weld.

- Flux-Cored Arc Welding: Similar to MIG but uses a special tubular wire filled with flux.

How Hard is it to Learn Welding?

Factors That Influence the Difficulty of Learning Welding

1. Technical Complexity

Different welding techniques vary in complexity. MIG welding is often considered easier for beginners due to its continuous wire feed and easier control. TIG welding, on the other hand, is more challenging as it requires precise control of the torch and filler material simultaneously.

2. Manual Dexterity

Welding demands excellent hand-eye coordination and manual dexterity. The ability to manipulate the welding torch steadily and accurately is crucial for creating strong, clean welds. This skill can be developed with practice, but it may take time for beginners to achieve proficiency.

3. Knowledge of Materials

Understanding the properties of different metals and how they react to heat is essential. Welders must know how to adjust their techniques based on the material they are working with, whether it’s steel, aluminum, or another metal. This knowledge comes with experience and study.

4. Reading Blueprints

Welders often need to read and interpret blueprints and technical drawings. This requires an understanding of welding symbols, measurements, and construction plans. While this can be learned, it adds another layer of complexity to the trade.

5. Safety Precautions

Welding involves high temperatures, intense light, and potentially hazardous materials. Learning to weld safely is a critical part of the training process. Welders must be knowledgeable about protective gear, ventilation, and safe handling of equipment to prevent accidents.

Tips for Learning Welding

1. Enroll in a Welding Program

Formal training through a trade school, community college, or technical institute can provide structured learning and hands-on experience. These programs cover basic to advanced welding techniques, safety practices, and blueprint reading.

2. Practice Regularly

As with any skill, practice is essential. Set up a welding station where you can practice different welding techniques. Start with simple projects and gradually take on more complex tasks as your skills improve.

3. Learn from Experienced Welders

Mentorship can be invaluable. Learning from experienced welders allows you to gain practical insights and tips that you might not find in textbooks. Apprenticeships and internships are excellent opportunities to learn on the job.

4. Use Quality Equipment

Invest in good quality welding equipment and protective gear. Reliable tools can make the learning process smoother and more efficient. Ensure your helmet, gloves, and protective clothing meet safety standards.

5. Study Welding Theory

Understanding the theory behind welding can enhance your practical skills. Study the properties of different metals, welding techniques, and the science of heat and fusion. Many resources are available online, including videos, tutorials, and forums.

Challenges and Rewards

Challenges

- Initial Learning Curve: Welding has a steep learning curve, especially for techniques like TIG welding.

- Physical Demands: Welding can be physically demanding, requiring strength and stamina.

- Precision Required: Achieving clean, strong welds requires precision and attention to detail.

- Safety Concerns: Ensuring personal and workplace safety adds to the complexity of learning welding.

Rewards

- High Demand for Skilled Welders: Welders are in demand across many industries, offering job security.

- Competitive Pay: Skilled welders can earn a good salary with opportunities for overtime and bonuses.

- Variety of Work: Welders can work in diverse environments, from construction sites to manufacturing plants.

- Sense of Accomplishment: Creating strong, durable structures provides a tangible sense of achievement.

Conclusion

Is welding hard to learn? The answer depends on several factors, including the complexity of the welding technique, your manual dexterity, and your commitment to practice and study. While welding does have its challenges, with the right training, practice, and dedication, it is a highly rewarding skill to master. By understanding the demands and embracing the learning process, you can successfully become a proficient welder and enjoy a fulfilling career in this essential trade.

James is a welding expert, accomplished author, and trusted guide with over 8 years of experience in the industry. With his in-depth knowledge and engaging writing style, James has become a true authority in the field, offering readers and clients invaluable expertise and insights to take their welding skills to new heights.

by James | Aug 24, 2023 | Buying Guide

Welding, an intricate fusion of science and art, involves the joining of metals through intense heat. But behind the mesmerizing sparks and molten metal lies a lesser-known yet critical component: welding slag. In this detailed article, we delve into the depths of welding slag, unraveling its composition, formation, purposes, and techniques for removal. Whether you’re a seasoned welder or a curious enthusiast, let’s shine a light on the enigmatic world of welding slag. Also, read this guide about what tack welding is.

The Essentials of Welding Slag

Understanding the Phenomenon

Welding slag is a byproduct of the welding process that plays a significant role in achieving strong and clean welds. It’s a vitreous material that forms on the surface of the weld bead, shielding it from external contaminants and atmospheric gases during the cooling process. This protective layer is a result of the chemical reactions between the molten metal, the electrode, and the flux coating.

Composition and Formation

Welding slag is composed of various elements based on the type of welding and the materials involved. It typically consists of oxides, silicates, and flux compounds. During welding, the flux coating on the electrode disintegrates, producing gases that help protect the molten metal from oxidation and impurities. As the metal cools, the slag forms and solidifies, encapsulating any impurities and preventing them from affecting the weld’s integrity.

Aiding in Welding Quality

Welding slag serves as a dual-purpose shield. It not only safeguards the molten metal but also contributes to the weld’s structural integrity. The slag’s insulating properties slow down the cooling process, allowing the weld metal to solidify uniformly. This controlled cooling minimizes the risk of cracks and enhances the weld’s mechanical properties, such as strength and toughness.

Read More: What is welding beads

The Lifecycle of Welding Slag

Formation: Birth of a Protective Layer

As the welding arc generates intense heat, the electrode’s flux coating disintegrates, releasing gases that shield the molten metal from oxygen and contaminants. Simultaneously, the flux forms a liquid slag that covers the weld pool’s surface.

Solidification: Building Strength and Protection

As the molten metal cools, the slag solidifies into a protective layer. This layer traps impurities, preventing them from affecting the weld. The controlled cooling also promotes uniform solidification of the weld metal, enhancing its structural integrity.

Removal: Revealing the Pristine Weld

After welding, the slag layer is chipped or brushed away using specialized tools. This reveals the clean and sound weld beneath. Proper removal is crucial to ensure the weld’s quality and integrity.

Applications of Welding Slag

Metallurgical Benefits

Welding slag goes beyond its protective role. It contributes to the metallurgical characteristics of the weld. The controlled cooling provided by the slag minimizes the chances of cracking and distortion, resulting in a weld with superior mechanical properties.

Use in Submerged Arc Welding (SAW)

Submerged Arc Welding utilizes a granulated flux that generates a blanket of slag over the weld bead. This slag blanket prevents spatter, provides a controlled environment for the weld, and aids in achieving high-quality joints in various applications.

Surface Cleaning and Abrasive Material

Recycled welding slag finds applications as an abrasive material in industries like shipbuilding and construction. It effectively removes rust, paint, and other contaminants from surfaces, making it an environmentally friendly alternative to traditional abrasive materials.

Methods of Welding Slag Removal

Chipping Method

The chipping method involves using a chipping hammer to carefully remove the solidified slag from the weld bead’s surface. This method requires skill to avoid damaging the weld itself.

Wire Brushing

Wire brushing employs a wire brush to mechanically scrub away the slag layer. This method is effective for lighter slag residues and leaves a clean surface ready for inspection.

Grinding Technique

In this method, a grinding wheel or abrasive disc is used to grind away the slag layer. It’s suitable for thick slag deposits and ensures a smooth, polished finish.

Conclusion: Unveiling the Crucial Role of Welding Slag

In the intricate world of welding, the unassuming welding slag plays a vital role in ensuring strong, clean, and quality welds. From its formation to its applications, we’ve explored the diverse aspects of this essential component. The protective shield it provides, along with its metallurgical benefits, contribute to welds that stand the test of time. As you embark on your welding journey, remember the significance of welding slag in achieving perfection in every weld.

Read More: What is welding beads

FAQs About Welding Slag

Is welding slag harmful to health?

Welding slag, once solidified, is generally not harmful. However, during the welding process, the fumes and gases produced can be hazardous. Proper ventilation and safety measures are essential.

Can I reuse welding slag?

While recycling welding slag is possible, it’s essential to consider its composition and intended use. Some types of slag can be recycled as abrasive materials, but not all slag is suitable for reuse.

Why does slag vary in appearance?

The appearance of welding slag can vary due to factors such as the type of welding, the materials being welded, and the composition of the flux coating. Different metals and fluxes result in different slag colors and textures.

What happens if I don’t remove the welding slag?

Leaving welding slag on a weld can lead to decreased weld quality. The slag can trap contaminants and affect the integrity of the joint, potentially leading to weld defects or failures.

Can slag affect the appearance of the final weld?

Yes, welding slag left on the surface of the weld can impact its appearance. It may result in a rough or uneven surface texture. Proper slag removal ensures a clean and aesthetically pleasing weld.

Are all welding slags the same?

No, welding slags can vary significantly based on factors like the welding process, the materials used, and the type of flux coating. Different types of slag have distinct characteristics and purposes.

James is a welding expert, accomplished author, and trusted guide with over 8 years of experience in the industry. With his in-depth knowledge and engaging writing style, James has become a true authority in the field, offering readers and clients invaluable expertise and insights to take their welding skills to new heights.

by James | May 7, 2023 | Buying Guide

Welding is an essential process in various industries and requires using the right tools to achieve quality results. One of the critical tools used in welding is the welding stinger also known as an electrode holder or welding electrode clamp.

As a professional welder, I’ve come to appreciate the importance of having the right tools to complete any welding project. A welding stinger is a handheld device that holds the welding electrode and transfers the electrical current to create an arc between the electrode and the welded metal.

The quality of the welding stinger is critical to any welding project’s success. Choosing the best welding stinger is essential for achieving efficient, safe and high-quality welds.

This article will explore the features that make the best welding stinger and provide a comprehensive guide to help you select the ideal welding stinger for your welding needs.

Top 7 Best Welding Stingers in 2023

Best Overall

Stv002 Insulated Holder Welding Stinger

The STINGER Stv002 electrode holder is a heavy-duty tool that will give you the confidence you need when welding. It securely holds the electrode in place, eliminating any chances of it popping out during your session. The ergonomic rubber handle ensures that your grip is strong and comfortable throughout the welding process, while the impressive amperage range of 0-350 and electrode capacity of 5 MIL/3/16″ make it more than capable of handling tough jobs.

The reliable electrical connection provided by the cable capacity of 1/0 ga. also gives me peace of mind while I weld safely. To top it off, a thermoset insulating cover provides added protection against electrical shocks and the fact that it’s made in the USA only adds to its quality. With this welding stinger, I have a reliable partner for all my welding needs. It’s an essential tool for any welder and one you won’t regret investing in.

Pros & Cons

Pros- • Excellent quality

- • Every piece of it is replaceable

- • Heavy duty will last forever

- • Excellent for pipeline welding

- • Worth the price

Cons- • Needs better insulation on the lever and the spring to be covered

Best Electrode Holder

Lenco welding stinger Model

I have a confession to make: I’m head over heels in love with a welding stinger. Yes, you heard that right – the best welding stinger. Specifically, the Lenco Model AF-25. This electrode holder has changed the game for me. The angled design is a game-changer – it gives me much better visibility while I’m working, which makes for a smoother and more accurate weld. And let’s talk about materials for a second.

The copper alloy build means it can withstand high temperatures without wearing down. You won’t have to worry about replacing it anytime soon. Oh, and the spring-loaded mechanism? It’s genius. It keeps your electrode locked and loaded so you can focus on the task at hand. With a 250 amp capacity, there’s no need to swap it out constantly. Plus, with a size range of up to 3/16″ electrodes, I’m set for all kinds of projects.

Pros & Cons

Pros- Heavy duty jaws and strong spring action and great feel in the hand

- Great plastic material

- Deep grooves that hold welding rods firmly

- Super durable, strong clamping power

- Not a problem changing rods 1 handed

- Comfortable to use

- A great upgrade

- Quality USA-made product

Cons- It appears to be used rather than brand new.

Best Operator

Victor Thermal Tweco Welding Stinger

When I first got my hands on the Victor Thermal Dynamics 91101123 Tweco Tong T316MC Electrode Holder Copper Alloy, I was amazed by its superior quality and design. It had a comfortable one-piece handle and an ergonomic grip that allowed me to maneuver it easily without fatigue. The copper alloy material also made it sturdy and built to last. Plus, it had fully insulated springs which added an extra layer of safety.

The efficient 6-position jaw pattern made sure that the electrode stayed put, and I could focus on precision welding without needing to readjust. This electrode holder was a must-have for anyone serious about welding. With its superior thermo-set material and added safety features, this electrode holder was sure to never disappoint. I highly recommend it for any welding job.

Pros & Cons

Pros- • Very well-built stinger

- • The Curvy design makes it Easy to grab

- • Finest electrode holder.

- • Nice notches in the heavy-duty jaws.

- • Good value for the price

Cons- • Use a hex screwdriver to loosen the handle to remove it

Best Value for Money

T300 Electrode Holder Stinger for Welder

As someone who has tackled a few welding projects in my day, I can confidently say that the T300 Electrode Holder Stinger from Lincoln Electric is an absolute game-changer. Unlike other welding tools I’ve used, this device offers unbeatable reliability and durability, guaranteed to offer superior performance every time.

With its impressive maximum current capacity of 300 amps and ability to handle DC only, there’s no welding project that the T300 can’t tackle. What’s more, its strong spring ensures your rod stays put and the maximum electrode voltage capacity guarantees a perfect weld every time. But perhaps its best feature is its versatility: it can be used both as an electrode holder and a ground clamp, making it a must-have in any welding arsenal.

And with its lightweight, ergonomic design, using it is an absolute breeze. Trust me, the T300 Electrode Holder Stinger is the best welding stinger you’ll ever need.

Pros & Cons

Pros- • Good strong spring

- • Maximum electrode voltage capacity

- • The nose is not insulated

- • It can be used as a ground clamp

Cons- • It is difficult to bend a rod over 1/8″ without repositioning your hands.

Best Lightweight

Lincoln Electric Electrode Holder

Being a welder can be a tough job, but having the right equipment can make all the difference. That’s why I choose the Lincoln Electric electrode holder. It’s not only lightweight but durable too, with a whopping 400 amp capacity. And the copper tongs provide high conductivity, ensuring the best welding results every time.

Safety is also a top priority when it comes to welding and this electrode holder doesn’t disappoint. Its heat resistance and insulation keep potential hazards at bay. Plus, the handles made of fiberglass provide the grip and handling control I need to tackle any welding project with ease. Put simply, the Lincoln Electric electrode holder is a no-brainer choice for any welder looking to get the job done right.

Pros & Cons

Pros- • Nice and solid

- • Well made and easy to install

- • The twist to change rods works fantastically

- • Works well and is durable

- • Safe product

Best Design

KSEIBI Amp Welding Electrode Holder

I’m more than impressed with the KSEIBI 331215 300 Amp Welding Electrode Holder and it has quickly become one of my favorite electrode holders. It is built from top-notch materials that guarantee durability and dependable performance. The 400-amp capacity means I can work on larger projects without worrying about it failing and the temperature-resistant design helps keep me and my equipment safe.

The Allen wrench, cable connection ferrule and deep grooves make for an incredibly efficient connection process and I can easily place my electrodes with confidence. It’s a must-have for any serious welder.

Pros & Cons

Pros- • Fit perfect

- • Meet exceptional standards of quality.

- • It functions beautifully.

- • Installs easily.

- • Nice size grip.

- • Great value for the money.

Best Stick Welding

SÜA 500 AMP Welding Electrode Holder

I’ve been using the SÜA 500 AMP Welding Electrode Holder for a few weeks now and I’m already hooked. This high-quality electrode holder is all you need to complete any welding project with precision and efficiency. The secure locking mechanism ensures my electrodes stay in place while I work and the heavy-duty nylon body ensures the holder is highly durable and won’t need to be replaced frequently.

With a maximum amperage of 500 A, this welding holder can handle any welding application I throw at it. It also accommodates cables of up to AWG 4/0 making it compatible with multiple welding machines and accessories. The high-strength coiled spring provides maximum grip on the electrode, keeping it secure throughout the welding job.

The high-conductivity jaws provide superior current transfer from start to finish, allowing me to achieve a perfect weld every time. And best of all, the electrode holder comes with a cable connector and Allen wrench so I can get started right away without having to purchase any additional accessories. The Electrode Holder AF-50 Style is an excellent tool for any welding enthusiast or professional. Its robust design and impressive features make it a must-have tool in your welding kit.

Pros & Cons

Pros- • Fits perfectly and works well

- • Nice weight and makes precision arc control easier

- • Holds the welding stick well

- • Thick plastic on the handle

- • Optimal performance and maneuverability

Cons- • It can handle 500 amps, but it is not compatible with a 4.0 cable

Types of best stick welding stinger

There are several types of welding stingers available on the market and the best one for you depends on your welding needs, the type of welding process and your personal preferences.

Here are some of the most common types of welding stingers:

Clamp-style stinger

This type of welding stinger uses a clamp to hold the welding electrode and transfer electrical current to the metal being welded. It’s a classic design and is suitable for stick welding applications.

Screw-type electrode holder

This type of welding stinger has a screw mechanism that tightens and holds the welding electrode in place. It’s suitable for stick welding applications and allows for a secure hold of the electrode.

Flex-neck stinger

This type of welding stinger has a flexible neck that allows you to adjust the angle of the electrode making it ideal for welding in tight spaces.

Twist-lock stinger

This type of welding stinger has a twist-lock mechanism that locks the electrode in place, making it easy to change the electrode quickly.

Insulated stinger

This type of welding stinger has an insulated handle to protect your hands from electrical shocks and heat.

By understanding the different types of welding stingers available, you can select the best one that meets your welding needs and provides a safe, efficient and reliable welding experience.

Things to Consider Before Buying the Best Stick Welding Stinger

Choosing the best welding stinger depends on several factors, such as the type of welding process, the welding environment and personal preferences.

Here are some essential factors to consider when selecting the best welding stinger:

Welding process

The type of welding process you use will determine the type of welding stinger you need. Stick welding requires a different stinger than TIG or MIG welding.

Material

The material being welded will also determine the type of welding stinger you need. For instance, welding thicker metals may require a stinger with a higher amperage rating.

Comfort and Ergonomics

Consider the comfort and ergonomics of the welding stinger. A stinger that is too heavy or too small can be uncomfortable to hold for extended periods, affecting your welding quality.

Amperage rating

Make sure the welding stinger’s amperage rating matches the amperage of the welding machine to prevent overheating and other issues.

Cable length

The length of the cable is essential, as it determines how far you can reach with the stinger. Ensure that the cable is long enough to reach your work area comfortably.

Durability

A quality welding stinger should be durable and resistant to wear and tear. Look for a stinger made from high-quality materials that can withstand frequent use and harsh environments.

Price

The price of a welding stinger can vary depending on the features and quality. Consider your budget and balance it with the features you need.

By considering these factors and doing proper research, you can find the best welding stinger that meets your welding needs and preferences.

Conclusion

Whether you are a beginner or a professional welder, finding the best welding stinger is an important step in producing high-quality welds safely. We hope this list has helped you find the best stick welding stinger for your project.

Whatever your choice may be, remember to always wear safety gear and use common sense when working with welding equipment. Also take into account the type of joint you are trying to assemble, as well as how much current will be needed.

Finally, be sure to keep up with the maintenance of all welding equipment and replace it, if necessary before beginning any project. All in all, having the right stick welding stinger can make a huge difference in your end results and success with your projects. So choose wisely!

Frequently Asked Questions

What is the strongest stick weld?

The strength of the best welding stinger depends on various factors such as the type of electrode used, welding technique, joint preparation and base metal properties. However, in general, low hydrogen electrodes are considered to be the strongest stick welds due to their excellent mechanical properties and reduced tendency to crack.

What is the best all-around stick welding rod?

A commonly used and versatile stick welding rod is the E6013 electrode. This type of electrode can be used on both AC and DC welding machines and can be used to weld a wide range of metals, including mild steel, galvanized steel and some low-alloy steel. It has a medium penetration and leaves a smooth and clean weld bead.

What does a stinger do for welding?

A stinger also known as an electrode holder is used in welding to securely hold the electrode and transfer the welding current to the electrode.

What are welding stingers made of?

Welding stingers or electrode holders are typically made of materials that provide high electrical conductivity and heat resistance, such as copper alloys or brass. The handle may be made of heat-resistant plastics.

Which stick is used in welding?

In stick welding also known as Shielded Metal Arc Welding (SMAW). The electrode also called a welding rod is used to create the arc that melts the base metal and fuses it together. The type of electrode used depends on the base metal being welded and the desired properties of the weld. Different types of electrodes include mild steel, stainless steel, cast iron and aluminum electrodes, among others.

James is a welding expert, accomplished author, and trusted guide with over 8 years of experience in the industry. With his in-depth knowledge and engaging writing style, James has become a true authority in the field, offering readers and clients invaluable expertise and insights to take their welding skills to new heights.

by James | Sep 17, 2022 | Buying Guide

Welding is a hazardous job with very high risks involved. Millions of workers are subjected to safety risks involved in welding. At the same time, we cannot eliminate the welding profession since it is a job that our society needs. We must encourage workers to take as many preventive measures as possible. Providing proper training and educating workers on the safety risks are a couple of ways to equip them to face the dangers of welding.

Informing welders about safety risks is an essential step toward preventing any accidents from taking place. They need to know what to avoid and how to protect themselves from unseen dangers. Every welder should be aware of the risks involved. In this article, we will inform you about safety risks that a welder may potentially have to expose themselves to. Let’s dive in.

1. Confined Space

Working in a confined space is a health hazard. There is a lack of oxygen in the room, followed by the fact that you are working with inert gases while welding. This can be extremely dangerous and a safety hazard. Gasses tend to react with each other and may potentially create harmful chemicals like rust which is why a ventilated environment is crucial.

Oxygen inside tanks and pipes makes it all the riskier. To avoid this, try to find an alternative to working in such spaces. If that is not attainable, use a safety system of work. There are also special welding helmets for tight spaces. It is always recommended to use all safety gears while welding

2. Fire And Explosions

Before you begin welding, you should remove all flammable material from the area you work in, such as wood and fabric. Any hot work executed during welding should be monitored and done very carefully. Although hot work cannot be done anywhere safely and must have a dedicated space, it is possible to keep a close eye on clear inflammable material.

Welders should also monitor hot work until an hour later to ensure no sparks or small flames have been ignited or are on the verge of igniting. Another health hazard under this is the smoke from sparks or hot work executed.

3. Electrical Hazard

Welding naturally requires an electrical circuit as a part of the welding process. Therefore, whenever a welder handles electrical equipment, they may be exposed or at risk of receiving electrical shocks. Electrical circuit breakers can protect welders from getting electrocuted. The welder is responsible for ensuring that the equipment is free from defects.

Welders are also instructed to report any as soon as one is spotted. Avoid welding in damp areas and inside metal structures to decrease the chances of electric shocks. An insulating mat would be helpful in this instance.

4. Physical Hazards

A lot of accidents tend to be the cause of slips and trips. This can also be because of inadequate arrangement or structure of the workplace that can cause a welder to slip and fall. Companies should work towards managing this to minimize or eliminate the risks of tripping over things like wires, imbalanced flooring, etc. It is not costly. It requires a lot of care and monitoring, which is crucial to implement in a welding environment.

Other physical hazards include cuts which are highly common due to the nature of the profession. Crushed toes and crushed fingers also happen a lot because of the involvement of dealing with or carrying heavy objects. You can prevent this by using protective gear or PPE (Personal Protective Equipment) at all times and at all costs.

Conclusion of Safety Risks While Welding:

Welding in a confined space can be dangerous due to the lack of ventilation since there is a dealing of inert gasses, which can make toxic chemicals. There are also huge risks of fire and explosions, especially when you conduct hot work. Since welding requires handling electrical equipment, this increases the chances of getting electrocuted.

Other physical accidents are cuts, burns, slips, and crushed fingers or toes. Therefore, always wear welding gloves and working boots during welding. Being educated on the risks is essential to ensure you minimize the chances of any of these events taking place. We hope this article helped give you enough insight into the safety risks involved in welding. Thank you for reading!

James is a welding expert, accomplished author, and trusted guide with over 8 years of experience in the industry. With his in-depth knowledge and engaging writing style, James has become a true authority in the field, offering readers and clients invaluable expertise and insights to take their welding skills to new heights.

by James | Jun 12, 2022 | Buying Guide

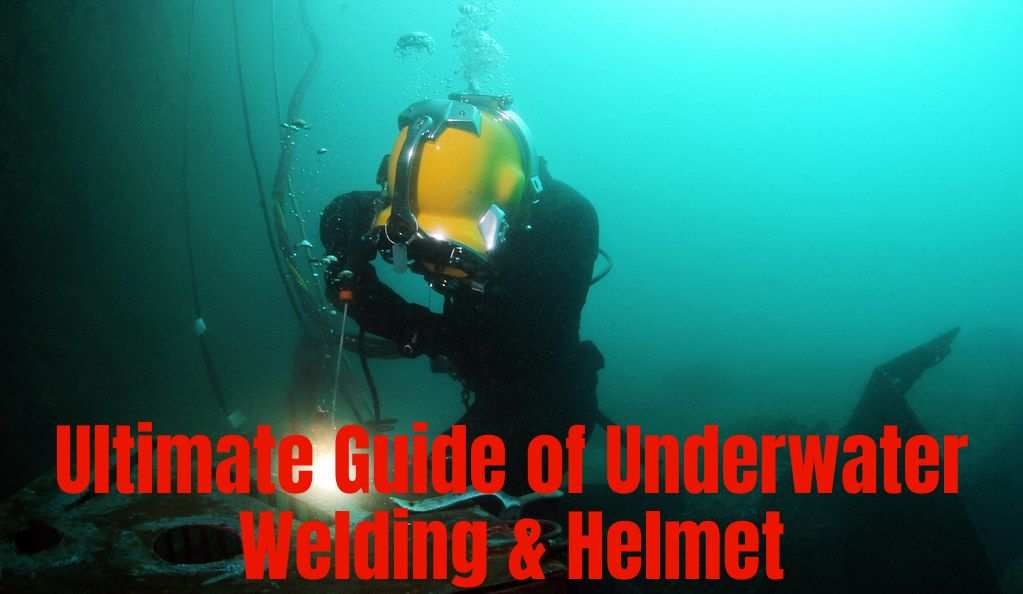

A wrong underwater welding helmet is a total tragedy. The helmet for underwater diving is one of those items that is so vital and any mishap with it could seriously affect your performance. If you’re a diver, then you are aware of this already. Let’s begin with the various kinds and then look into the information about the most widely worn caps.

Underwater Welding Helmet

A diving helmet is not just a device that safeguards the diver from injuries. It also lets the diver breathe air via the umbilical as well as a system of communication that connects the diver with the tenders at the surface.

Divers depend on their team members to “make it hot” when it’s time to switch on the welding equipment’s power or make adjustments when conditions change. Divers usually wear the same helmet as commercial underwater welders but with a welding visor for underwater welding helmet.

The visor is fitted to the helmet of a diving diver to shield divers’ eyes from the arc’s brightness. Projections are available in various colors and styles according to the design and the diver’s preferences.

What Types Of Commercial Diving Welding Helmets Are There?

Welders who work underwater require a sturdy diving helmet to perform their job. On the surface, welding helmets (hoods) shield welders’ eyes and faces when they are working on a welding job. Welding helmets underwater serve this function and allow the welder and diver to breathe.

Most divers use the same diving helmet they wear on a typical commercial dive, but with an additional feature: a welding screen that can be attached to the mask’s front to provide eye protection. The screens can be adjusted up and down, similar to welding hoods, and are available in various shades.

Diving Helmet Types

Underwater welders use different kinds of underwater welding helmets according to the underwater environment and working conditions.

· Open Circuit

The helmet is equipped with gas valves that are non-return and anti-fogging lenses. It also has side weights, an internal cushion, and other contemporary features. It’s the most sought-after safety helmet used by commercial divers. Since it is equipped with an idle valve, the air exhaled is released into the sea.

· Reclaim

The type of helmet is based on the same principle similar to that of the Open Circuit, but it recycles the gas exhaled by the diver and then pumps it back to the system at the same pressure.

· Free-Flow Helmet

The helmet is designed with the most straightforward style. This helmet is highlighted by a more extensive, transparent visor that offers greater visibility. Because of its ease of use, divers can pull the helmet apart and put it back together using a screwdriver and wrench. It’s primarily used in areas with hazardous materials and water that is shallow.

Wet welding uses only an air source supplied by the surface (SSA), and it’s important to note the technology used for SSA is specially designed and only utilized by experts. SSA (as opposed to the more common SCUBA) is vital for underwater welders since it permits communication with the welding machine’s surface crew.

How To Choose A Commercial Underwater Helmet

Once you become aware of different underwater welding helmets models and how their functioning. It’s time to talk about the details of these hoods. However, regardless of the style and model, you select, Here are some tips to remember while making your decision. It is essential to choose a suitable underwater hat for your requirements that doesn’t make your work difficult.

The Return Policy

Check that the store where you purchase your new underwater welding hood comes with at least two weeks of the return policy. It is essential to test the helmet thoroughly. Check everything out and determine if it’s working for you. Commercial divers’ equipment is costly, and the hats are the most expensive part that underwater welding professionals own.

Price

The commercial underwater hats’ prices could range from $6,000 to $10,000 for a brand new one. It could also be feasible to purchase an older helmet because of its long-lasting nature. Underwater welders can make a lot of money so, they must use a good quality underwater welding helmet. Also check the how much underwater welders make in one year.

In this way, you’re in the range of $1,000 to $3000. It may seem more attainable, but it is best only to buy a used helmet if you believe you can be sure that previous owners took good maintenance of the item. Be sure you’re well-prepared for this type of investment. If you’re a beginner diver, consider your experience in the field and potential income. According to our experience in welding industry, we suggest you to always buy a new welding hood.

Are you confident that you’re in the correct position to purchase the equipment you need?

Most of the welding jobs offer welding equipment, same is the case with underwater welding helmet. While on the job, you’ll be held accountable for the hat. It is essential to treat underwater hat with full care. Nearly all jobs will include an ad-hoc policy regarding the care of the cap.

A policy could say that each night after the work is completed, it is your responsibility to clean your hat, examine its condition and feed it. The Company’s hood will save you money, but it also comes with an obligation.

In addition, you need to be sure that the Company is working correctly because you have seen someone else wearing that hat previously and another before them, etc. Therefore, you can avoid purchasing the hat first when you are offered an opportunity that provides the underwater cap, and you are prepared for the responsibilities and the risks that go along with the purchase.

Breathing Function

Let’s start with the technical aspects. One of the most critical aspects is the quality of your breathing in the underwater welding helmet. Test different helmets to find one that gives you to breathe with great effectiveness. Because it can be fatal for your life if it’s not working well. It can be the cause of underwater welder death.

Your breathing should be simple and easy to regulate. We discussed the open circuit or the on-demand airflow helmets earlier and the free flow models. It is common to use air hats on demand often, so make sure that their valves and regulators are of top quality and allow adjustments. Nothing can make your job more difficult than having difficulties breathing under the car’s hood.

Regulators and Valves

The helmet’s regulators should be made from anti-corrosion material. This is a standard feature for modern helmets. It is possible to choose between stainless steel and hard plastics; however, many different materials can be utilized.

Your regulator must be able to make a wide variety of adjustments. This will allow you to modify the breathing setting to meet your specific needs. Valves should be located in an easy-to-access area. However, most models have considered this already. In particular, an emergency air valve.

If you are a diver who welds is a must to have an extra tank in your bag. The tank is connected to the emergency valve that is in your helmet. If the umbilical cord were to cut off or something else occurred, leaving the person without air, they can switch off the emergency valve and then breathe out of the tank.

This tank is usually equipped with a small quantity of oxygen. Only enough to bring you up to the surface. Other valves that your helmet requires are the gas supply return valve and a ventilation valve. The ventilation valve is utilized to clear the view and let the face breathe. The valve for the supply that does not return allows breathing gas to enter through the umbilical cord.

Communication Skills

Commercial diving requires a lot of communication. It is constant direct contact with your topside team. The tender will always communicate with you, direct your workflow while paying attention to your breathing, and remain in readiness if you need to contact assistance.

Underwater Welding Helmet Size

The diving helmet should be comfortable and snug to your head. It shouldn’t be too tight, but it should feel right. It’s something only you will feel and determine that everything is fine. The hat shouldn’t be any bigger than you require.

You can work for months or even minutes on a structure, but regardless, to be effective, your helmet has to be shaped to fit your head.

Everyone who is an expert in sizing takes it seriously, and that’s why you should too. Nearly every commercial diving helmet can allow you to replace one foam padding for another to attain the right fit. So even if you’re not happy with the design, it is still possible to alter it.

The Mobility You Display

Imagine that welder divers aren’t capable of achieving the entire movement. However, many don’t think that an incorrect configuration or the choice of the wrong type of underwater welding helmet can be the reason for this. This can result in a lower level of performance and could hinder your professional career.

Your performance will be better when your mobility is comparable to the one you have in the absence of commercial diving gear. Your neck dam needs to fit your neck nicely to enable this to happen. This might mean trying various models before settling on the right one for you.

The situation could become more complicated with the diving suit you’re using. For instance, if your work requirements necessitate you wearing a dry suit, you will be protected by protection from hazmat particles. However, your mobility is affected unless the suit’s material is suitable for your body and an appropriately sized case.

Conclusion

Every underwater welding job given to a commercial dive team will have distinct specifications and conditions that determine what equipment and tools are required. It also depends on whether the project needs a hyperbaric welding method or a wet weld process. The underwater welding helmet is among the essential equipment required to accomplish this task.

James is a welding expert, accomplished author, and trusted guide with over 8 years of experience in the industry. With his in-depth knowledge and engaging writing style, James has become a true authority in the field, offering readers and clients invaluable expertise and insights to take their welding skills to new heights.