Working in tight, cramped areas like pipe racks, inside tanks, or under equipment is very different from welding on an open bench. A bulky helmet can hit your chest, catch on supports, or block your view right when you need it most. In these spots you want a hood that is light, compact, and shaped so it stays out of the way while still protecting your eyes and face.

Short Answer: Top choices for Welding Helmet for Tight Spaces in 2026 include, Ridge Products Throne 2.0 and Tefuawe flip-up chopped fiberglass sugar-scoop hoods because they’re lightweight, low-profile, and can be trimmed for extra clearance. If you prefer auto-darkening, the Miller Classic ClearLight and YESWELDER LYG-M800H offer compact shells with clear optics, making them easier to use in confined areas without sacrificing puddle visibility.

This guide looks at some of the best welding helmets and hoods for tight spaces, including sugar scoop pipeline hoods, flip‑front helmets, and compact auto‑darkening masks. For each one, you’ll see what it does best, what to watch out for, and who it really suits, so you can pick the right hood for your work and budget.

Table of Contents

What to Look for in a Welding Helmet for Tight Spaces

Before we dive into specific helmet models, it’s important to understand the features that matter most in confined or awkward environments.

Viewing Area (Lens Size and Shape)

A larger viewing area means better situational awareness. In tight spaces, welders often cannot reposition freely, so a wide-angle view helps maintain visibility without awkward head movement.

Important aspects:

- Horizontal width for side visibility

- Vertical height for weld puddle tracking

- Multiple sensors for reliable auto-darkening

Low Profile and Compact Shell

A low-profile helmet contours closer to the head, minimizing interference with overhead obstructions or tight gaps. This improves comfort and prevents bumping during movement.

Auto-Darkening Performance

High-quality auto-darkening helmets provide:

- Rapid switching speed (measured in milliseconds)

- Consistent shade levels

- Adjustable sensitivity and delay

- Reliable performance even in reflective or low-light conditions

For close-quarters welding, fast and stable darkening reduces eye strain and improves precision.

Lightweight Design and Comfort

Long welding jobs in tight spaces can tie up neck and shoulder muscles. Lightweight helmets reduce fatigue and make it easier to hold a stable welding position.

Adjustable Fit and Headgear

Multiple adjustment points in the headgear improve comfort and allow a secure fit so the helmet stays in place even when turning or bending.

Shade Range

A helmet with a broad shade range (e.g., DIN 9–13 or approximately 8–13) ensures protection across various welding types like TIG, MIG, and stick welding.

12 Best Welding Helmets and Hoods for Tight Spaces

1. Tefuawe Black Flip Up Chopped Fiberglass Sugar Scoop Welding Helmet

Tefuawe Black Flip Up Chopped Fiberglass Sugar Scoop Welding Helmet

A chopped‑fiberglass sugar scoop hood with a flip‑up lens and ergonomic profile that stays clear of your chest and neck in tight positions.

Check PriceWhy it stands out

This Tefuawe hood is built specifically with pipeline and tight‑space welders in mind. The chopped fiberglass shell is both lightweight and tough, and the sugar scoop shape keeps the hood from constantly bumping your chest when you’re working in close.

Key points

- Material: chopped fiberglass, moisture‑proof and impact‑resistant

- Weight: about 2.1 lb (0.95 kg)

- Viewing area: standard 2×4 in lens opening

- Flip‑up front for quick inspection or grinding

- Adjustable eye‑to‑lens distance to help fit respirators and glasses

- Includes a waterproof hood bag for storage and transport

Pros

- Very light for a fiberglass hood, good for long days

- Shape and cut help avoid contact with chest and shoulders in cramped positions

- Strong, durable shell holds up to field use

- Adjustable headgear and eye distance give a custom fit

- No electronics or batteries to worry about

Cons

- Does not include an auto‑darkening lens – you must add your own 2×4 filter

- Fixed 2×4 window is smaller than modern panoramic helmets

- Flip‑up hinge can feel stiff until broken in

Best for

Pipeline welders and field welders who spend a lot of time in tight spaces and want a simple, tough, lightweight hood they can pair with their preferred 2×4 lens.

2. TOOLIOM Large Viewing Auto‑Darkening Welding Helmet

TOOLIOM Large Viewing Auto‑Darkening Welding Helmet

A light, compact auto‑darkening helmet with a 3.94″×3.27″ viewing area and weld, cut, and grind modes for all‑around shop and field work.

Check PriceWhy it stands out

The TOOLIOM combines a large window with a relatively small, lightweight shell. That gives you a wide view while keeping the helmet compact enough to maneuver next to walls, beams, and pipe runs.

Key points

- Viewing area: about 3.94″×3.27″ (≈12.9 sq in)

- True Color lens for more natural view of the puddle

- Shade range: DIN 9–13 (weld), 5–9 (cut), 4 (grind)

- Four arc sensors with adjustable sensitivity and delay

- Power: solar cell plus replaceable lithium battery (included)

- Weight: about 1.28 lb (0.58 kg)

Pros

- Large viewing area helps you see more in cramped positions

- Multi‑mode (weld/cut/grind) makes it useful for full jobs, not just welding

- True Color lens reduces eye strain and improves clarity

- Light weight is comfortable for beginners and hobbyists

- Good value for the feature set

Cons

- Not as rugged as some premium industrial hoods

- Precise battery life is not clearly stated

- Headgear is basic and may need upgrading if you weld daily

Best for

DIYers, light‑duty shop welders, and beginners who want an affordable auto‑darkening helmet with a wide view that still works well in tighter areas.

3. Ridge Products Throne 2.0 White Flip Up Sugar Scoop Welding Hood

Throne 2.0 White Flip Up Sugar Scoop Welding Hood

A white fiberglass sugar scoop hood with a flip‑up front, designed to be ultra‑light, durable, and easy to trim or chop for customized tight‑space work.

Check PriceWhy it stands out

The Throne 2.0 is popular among pipeliners because it’s light, tough, and easy to modify. You can sand, trim, or chop the fiberglass shell to suit your preferred cut and balance, which is a big plus when you weld in awkward spots all day.

Key points

- Material: fiberglass shell, designed to be sanded and trimmed

- Weight: about 1.7–1.8 lb

- Window: 2×4 in lens opening (fits standard pipeline lenses and cheaters)

- Flip‑up front, lens not included (you add your own)

- Compatible with slotted hard‑hat adapters (Miller style)

- Hand‑powered – no batteries or electronics

Pros

- Very customizable shell, ideal if you like to chop your hood

- Lightweight design helps reduce neck fatigue

- Strong, durable body built for field conditions

- Works with a wide range of 2×4 lenses and cheaters

- Hard‑hat compatible with the right adapter

Cons

- Ships without a lens, so you must supply your own

- 2×4 window is modest compared with big auto‑darkening hoods

- White finish can show dirt and marks more quickly

Best for

Experienced pipeline and field welders who want a tough, mod‑friendly sugar scoop hood they can shape exactly how they like for tight, repetitive work.

4. Ridge Products Throne 2.0 Black Flip Up Sugar Scoop Welding Hood

Throne 2.0 Black Flip Up Sugar Scoop Welding Hood

The black version of the Throne 2.0 sugar scoop hood, offering the same light, durable shell in a darker color that hides dirt and spatter better.

Check PriceWhy it stands out

Functionally similar to the white Throne 2.0, this black version appeals to welders who prefer a darker look and want a hood that stays cleaner‑looking on dusty or oily sites.

Key points

- Material: fiberglass, same chop‑ready shell as the white 2.0

- Weight: around 1.74 lb

- Window: 2×4 in opening, accepts most pipeline lenses and cheaters

- Flip‑up front, lens not included

- Hard‑hat compatible with correct adapter

- Hand‑powered – no auto‑darkening built in

Pros

- Black color hides grime and arc marks more effectively

- Light and compact for overhead and close‑in work

- Easy to customize for fit, balance, and clearance

- Solid build quality with good user ratings

- Simple, low‑maintenance design

Cons

- Same small 2×4 window limitations as other pipeline hoods

- Requires a separate 2×4 lens (auto‑darkening or fixed)

- Some users may want softer, more padded headgear

Best for

Pipeline and structural welders who like the Throne 2.0 design but prefer a black, more discreet finish for daily work in tight areas.

5. YESWELDER Lightweight Flip Front Welding Helmet – Budget‑Friendly Flip‑Front Sugar Scoop

YESWELDER Lightweight, Durable Flip Front Welding Helmet

A compact flip‑front hood made from a lightweight composite material, aimed at welders who want a simple sugar scoop for tight work on a budget.

Check PriceWhy it stands out

YESWELDER’s flip‑front hood offers a sugar scoop style at a lower price point. The proprietary composite shell keeps weight down, and the small profile works well in cramped positions.

Key points

- Material: proprietary composite (lightweight and tough)

- Weight: about 0.67 kg (≈1.5 lb)

- Style: flip‑front, takes standard 2×4 lenses

- Color: black, simple matte finish

- Compact overall length for better clearance in tight spaces

Pros

- Very budget‑friendly compared with many pipeline hoods

- Light and low‑profile, good for occasional tight‑space work

- Flip‑front makes lens swaps easy

- Simple design, no electronics to fail

- Reasonably comfortable for short to medium sessions

Cons

- Not as rugged as heavier fiberglass hoods

- Basic headgear may not hold up to rough daily use

- No lens included; auto‑darkening requires a separate 2×4 cartridge

Best for

Beginners, hobby welders, or anyone wanting to try a sugar scoop style hood for occasional tight‑space jobs without investing in a more expensive pipeliner helmet.

6. The Throne 1.0 Flip Up Sugar Scoop Welding Hood

The Throne 1.0 Flip Up Sugar Scoop Welding Hood

A flip‑up sugar scoop hood with a built‑in retainer system, designed so you don’t lose the small parts and can run a full pipeline setup in tight spaces.

Check PriceWhy it stands out

The Throne 1.0 focuses on convenience: its built‑in retainer keeps the flip‑up assembly together so you’re not hunting for clips or rings. That’s handy when you’re moving around scaffolding or inside pipe racks.

Key points

- Material: fiberglass shell

- Weight: about 1.98 lb

- Window: 2×4 in lens opening with built‑in flip‑up + retainer

- Compatible with Ridge lenses, cheaters, and various thicknesses

- Headgear/hard‑hat compatibility with common adapters

- Hand‑powered; shade depends on the lens you install

Pros

- Retainer design helps never lose parts again when flipping or swapping lenses

- Durable and field‑ready with solid fiberglass construction

- Works well with hard hats and common headgear systems

- Made to fit thick and thin lenses securely

- Good ratings for comfort and durability

Cons

- Heavier than some minimalist pipeline hoods

- No auto‑darkening lens included

- Some users may prefer the slightly lighter Throne 2.0 shell

Best for

Pipeline welders who want a ready‑to‑run flip‑up hood with a secure lens system and don’t want to mess with loose retainers and small parts on busy job sites.

7. LIMXYZ Auto‑Darkening Welding Helmet

LIMXYZ Auto‑Darkening Welding Helmet, True Color

A small, light auto‑darkening helmet with a narrow 3.66″×1.69″ view and true color lens, ideal for quick welds and repairs in tight areas.

Check PriceWhy it stands out

This helmet packs a lot into a compact shell: true color optics, a wide shade range, and solar plus battery power. The smaller viewing window keeps the helmet profile short, which helps in confined spaces.

Key points

- Viewing area: 3.66″×1.69″ (narrow rectangular lens)

- Shade range: DIN 4/9–13, with 1/1/1/2 optical clarity

- Two arc sensors with adjustable sensitivity and delay

- Power: solar cell and replaceable CR2032 battery

- Weight: around 0.9 lb (very light)

- Material: PP shell (shock and flame‑resistant)

Pros

- Extremely light and compact, good in awkward positions

- True color view improves detail recognition

- Solar charging plus replaceable coin cell for backup

- Affordable price with solid feature set

- Suitable for TIG, MIG, MAG, and stick work

Cons

- Small viewing window can feel restrictive for long welds

- Two sensors may be less reliable in very obstructed angles than four‑sensor designs

- Shell material is lighter‑duty than heavy industrial helmets

Best for

Home and light‑industrial welders who need a very lightweight, compact auto‑darkening mask for occasional use in tight corners, but don’t require a large viewing area.

8. YESWELDER Large View Auto‑Darkening Welding Helmet

YESWELDER Large View Auto‑Darkening Welding Helmet LYG‑M800H

A large‑view, true‑color, 4‑sensor auto‑darkening helmet with blue light blocking, built for clear vision and all‑process welding in cramped or open spaces.

Check PriceWhy it stands out

The LYG‑M800H offers one of the largest viewing areas in this list while still keeping a reasonably compact shell. True‑color optics and blue‑light blocking help you see the puddle clearly even in shadowed or tight areas.

Key points

- Viewing area: about 3.93″×3.66″

- Shade range: 3/5–9/9–13 for weld, cut, and grind

- Four arc sensors with adjustable delay and sensitivity

- Power: solar cell plus replaceable CR2450 battery

- Battery life: up to 3000 hours (claimed)

- True color 1/1/1/1 optics

Pros

- Large window gives excellent visibility in complex joints

- Wide shade range makes it versatile for TIG, MIG, stick, cut, and grind

- True‑color lens reduces eye strain and glare

- Long battery life with solar assist

- Good balance of price and features for regular users

Cons

- Heavier than very small, fixed‑lens hoods

- Bigger shell may be a tight fit in extremely narrow pipe spaces

- Some users might find the headgear basic and want to upgrade

Best for

Intermediate and advanced welders who want a big, clear view and full auto‑darkening features for both tight and open work, and who do a mix of processes.

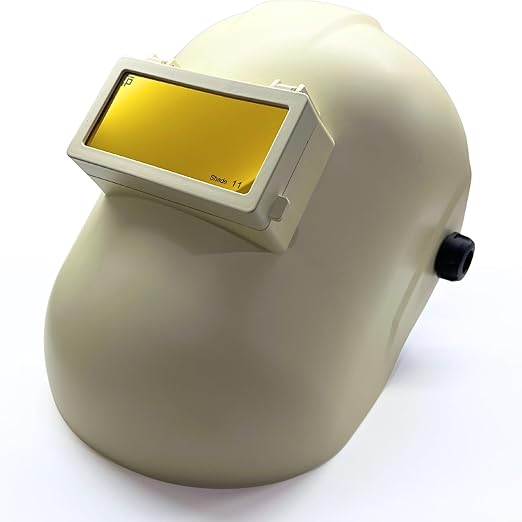

9. Fibre‑Metal Tigerhood Classic Thermoplastic Welding Helmet

Fibre‑Metal by Honeywell Tigerhood Classic Welding Helmet

A thermoplastic welding hood with a hard‑hat mount and extended throat protection, suited to tight industrial spaces where head and face protection are both required.

Check PriceWhy it stands out

The Tigerhood Classic is well‑known for its durability and ability to mount quickly to a hard hat using the Speedy Loop system. Its relatively compact shell and extended neck coverage make it a good choice in hot, smoky, cramped environments.

Key points

- Material: Noryl thermoplastic (heat and spark‑resistant)

- Weight: about 1.18 lb

- Window: 2×4 in shade 10 lens included (flip‑up glass holder)

- Hard‑hat mounting: Speedy Loop system (no tools needed)

- Meets ANSI Z87.1 and CSA Z94.3 standards

- Roomy interior to accommodate respirators and glasses

Pros

- Quick on/off over a hard hat – ideal for industrial sites

- Lightweight but tough shell that resists heat and impact

- Extended throat helps shield against fumes and spatter

- Flip‑up holder seals well against light leaks

- Good long‑term value and strong reputation

Cons

- Fixed‑shade lens; auto‑darkening requires aftermarket lens

- Classic 2×4 window is small by modern standards

- Hard‑hat mount may feel different if you’re used to ratchet headgear

Best for

Industrial welders, especially in plants and shipyards, who must wear a hard hat and need a tough, reliable hood that still works well in cramped spots.

10. Miller Classic Series Auto‑Darkening Welding Helmet

Miller Classic Series Auto‑Darkening Welding Helmet with ClearLight

A professional auto‑darkening helmet from Miller with ClearLight high‑definition optics and variable shade, built for reliable use in tight or open welding work.

Check PriceWhy it stands out

ClearLight optics are what many welders like most about this helmet. The view is bright and detailed, which matters a lot when your positioning is limited and you need to see every bit of the joint.

Key points

- Viewing area: about 6 sq in

- Shade ranges: weld 8–13, cut 5–8, grind 3

- Two arc sensors, 1/23,000‑second switching speed

- ClearLight lens tech for high‑definition color and contrast

- Ergonomic headgear for comfort during longer sessions

- No separate battery changes to manage

Pros

- Very clear, bright view of the puddle and surroundings

- Compact, well‑balanced shell that doesn’t feel bulky

- Trusted Miller build quality

- Simple controls and reliable darkening response

- Good for a wide range of processes

Cons

- More expensive than many budget auto‑darkening hoods

- Viewing area smaller than some large‑window helmets

- Only two sensors; needs reasonably straight line of sight to the arc

Best for

Serious hobbyists and pros who want a compact, trustworthy auto‑darkening helmet with excellent optics, and who often weld in positions where a clear, accurate view matters more than an extra‑wide window.

11. MIGVAN Auto‑Darkening Welding Helmet

MIGVAN Auto‑Darkening Welding Helmet, True Color

A large‑view, true‑color helmet with four arc sensors and solar plus rechargeable battery power, designed for multi‑process welding in shops or tight field work.

Check PriceWhy it stands out

The MIGVAN helmet combines a big viewing area, four sensors, and a power system that uses both solar and a rechargeable battery. This helps keep it responsive even when you’re moving around in and out of the light.

Key points

- Large viewing screen (exact size not listed but sizable)

- Shade range: from DIN 4 (light) up to 5–9/9–13 (dark)

- Four arc sensors for better coverage in awkward angles

- Solar‑powered with replaceable/rechargeable lithium battery

- True color optics and high optical class

- Includes spare inner and outer lenses plus storage bag

Pros

- Wide field of view helps you see more of the joint in tight conditions

- Solar plus battery power offers long runtime and reliability

- Versatile shade range for TIG, MIG, stick, cut, and grind

- Extra lenses and bag included add value

- Good reviews for clarity and comfort

Cons

- Heavier than very small hoods and pipeliners

- Bigger shell may be tight in very narrow pipe runs

- Headgear may need adjustment for best comfort on long shifts

Best for

Welders who want a full‑featured auto‑darkening helmet with a big window and solid power system, and who split their time between tight areas and general shop welding.

12. Jackson Safety PL280 Pipeline Welding Helmet

Jackson Safety PL280 Pipeline Welding Helmet

A U.S.‑made pipeline hood with a spring‑loaded flip front, 2″×4.25″ shade 10 filter, and ratchet headgear, designed for tight pipeline and overhead work.

Check PriceWhy it stands out

The PL280 is a classic style pipeline hood with a lift front and a slightly wider 2″×4.25″ window. It offers a good balance of protection, compact size, and compatibility with safety standards.

Key points

- Window: 2″×4.25″ polycarbonate with shade 10 filter

- Shell: nylon/polycarbonate, made in the USA

- Weight: about 1.91 lb

- Spring‑loaded flip front for quick up/down action

- Ratchet headgear for easy size adjustments

- Meets ANSI Z87.1 and CSA Z94.1 standards

Pros

- Slightly larger window than standard 2×4 while staying compact

- Flip‑front design is fast and convenient for inspection and grinding

- Good weight and balance for pipeline and overhead work

- Hard‑use build that stands up to jobsite abuse

- Safety‑standard compliant and made in the USA

Cons

- Fixed‑shade filter; auto‑darkening requires replacing with another lens

- Smaller view than large‑window auto‑darkening hoods

- Ratchet headgear is basic and may need tweaking for perfect comfort

Best for

Pipeline welders who want a proven, compact flip‑front hood that meets safety standards and works well in tight, dirty, and overhead environments.

How to Choose the Right Helmet for Tight Spaces

When you choose a welding helmet for tight spaces, think about three main points:

- Profile and clearance

- Sugar scoop and pipeliner hoods (Tefuawe, Throne 1.0/2.0, Jackson PL280, Tigerhood) have shorter noses and cutaway corners so they don’t slam into your chest or the work.

- Full auto‑darkening helmets (Miller Classic, YESWELDER M800H, MIGVAN, TOOLIOM, LIMXYZ) give more viewing area but can feel bulkier in very tight pipe or tank work.

- Viewing needs and lens type

- If you do long welds or complex work, a large auto‑darkening window (YESWELDER M800H, MIGVAN, TOOLIOM) makes it easier to see.

- If you’re used to a fixed‑shade 2×4 and want a small, rugged hood, the pipeline style hoods (Throne, Tefuawe, Jackson, Tigerhood) may still suit you best. You can always drop a 2×4 auto‑darkening cartridge into them.

- Work environment and safety rules

- For sites that require hard hats, look at hard‑hat compatible models like the Fibre‑Metal Tigerhood Classic and Jackson PL280.

- For general shop and mixed work, a comfortable auto‑darkening helmet with clear optics (Miller Classic, YESWELDER M800H, MIGVAN, TOOLIOM) may be most efficient.

If you mainly do pipeline or similar confined work, starting with a lightweight sugar scoop hood like the Tefuawe or Throne 2.0 and pairing it with a good 2×4 lens is a solid, proven setup. If you split your time between tight spots and open bench welding, consider a compact auto‑darkening helmet such as the TOOLIOM or Miller Classic for a better balance of visibility and convenience.

Why Standard Welding Helmets Can Be Problematic in Tight Spaces

When welding in close quarters such as inside tanks, under vehicles, inside ducts, or between structural beams, traditional full-size welding helmets can get in the way. Typical issues include:

Limited Visibility

Large front or side profiles can block peripheral vision, forcing welders to reposition their heads awkwardly to see the weld puddle.

Restricted Movement

Bulky helmets can hit against beams, walls, or machinery, interrupting workflow and causing frustration.

Neck and Shoulder Strain

Heavy, unbalanced helmets cause fatigue over long shifts, especially when constantly tilting the head to compensate for restricted views.

Glare and Reflection Issues

In tight environments, light can bounce off metal surfaces more intensely, requiring helmets that handle unexpected reflections.

Because of these challenges, welders in tight spaces benefit from helmets with compact designs, low profiles, wide viewing areas, and reliable auto-darkening sensors that quickly respond to arc starts and stops.

Common Mistakes When Choosing a Welding Helmet for Tight Spaces

Here are mistakes many welders make when selecting a helmet for confined work:

- Choosing a heavy helmet that causes neck strain

- Ignoring viewing area size and field of vision

- Selecting helmets with slow auto-darkening response

- Assuming all helmets protect equally in close-quarters glare

- Picking a low-quality budget helmet for prolonged industrial use

Avoiding these common errors improves safety, comfort, and job performance.

Safety and Long-Term Considerations

Ensuring long-term safety and effectiveness involves more than picking a helmet. Consider the following:

- Replace helmets with damaged or scratched lenses

- Keep sensors clean to maintain darkening accuracy

- Ensure shade settings match welding type and material

- Check headgear periodically for loose components

- Choose helmets with quality certification and reliable brand reputation

Good care extends helmet life and protects your eyes and head in every welding scenario.

FAQs

What makes a welding helmet good for tight spaces?

A welding helmet for tight spaces has a compact, low-profile shell, wide viewing area, lightweight build, and fast auto-darkening response so that you can see the weld without excessive head movement.

Can any auto-darkening helmet work in tight spaces?

While many auto-darkening helmets can be used in tight spaces, those designed with wider viewing areas, smaller front profiles, and ergonomic headgear provide noticeably better performance and comfort.

Why is viewing area important for confined welding?

In tight spaces welders cannot always position their head directly toward the weld puddle. A larger viewing area allows you to see more of the work without awkward repositioning.

Are premium helmets worth the extra cost?

Premium helmets typically offer superior optical clarity, faster darkening, more reliable sensors, and greater comfort. For professional or frequent welders in confined environments, the benefits often justify the investment.

How fast should auto-darkening lenses switch?

Faster switching speeds (in micro- or milliseconds) reduce eye strain and make it easier to start arcs in awkward positions, especially where reflections or varying light conditions exist.

Do all helmets fit over safety glasses?

Most modern welding helmets are designed to accommodate safety glasses, but check headgear space and fit to ensure comfort and protection in tight environments.

Is weight an important factor for tight spaces?

Yes. A lighter helmet reduces neck and shoulder fatigue, especially when working in awkward or extended positions common to tight spaces.

How often should I replace a welding helmet?

Replace it when the lens scratches, sensors fail, headgear breaks, or darkening becomes unreliable. Regular inspection and proper care extend life but do not eliminate eventual wear.

Can I weld with a tight-fit helmet and ear protection?

Yes, but ensure the combination does not restrict head movement or compromise visibility. Choose helmets compatible with earmuffs or hearing protection if needed.

Conclusion:

Welding in tight spaces requires more than just skill. It demands the right protective gear, especially a welding helmet that offers clear visibility, reliable auto-darkening, a low profile, and comfortable fit. The helmets reviewed in this guide represent a range of options, from budget-friendly models that still perform well in confined environments to premium units that deliver excellent clarity and comfort for professionals.

Choosing the right helmet reduces eye fatigue, improves arc precision, and enhances safety, allowing welders to focus on quality results without struggling with restricted headroom or visibility. Consider your typical welding environment, the process you use most often, and how long your sessions last when selecting the best welding helmet for tight spaces.

James is a welding expert, accomplished author, and trusted guide with over 8 years of experience in the industry. With his in-depth knowledge and engaging writing style, James has become a true authority in the field, offering readers and clients invaluable expertise and insights to take their welding skills to new heights.