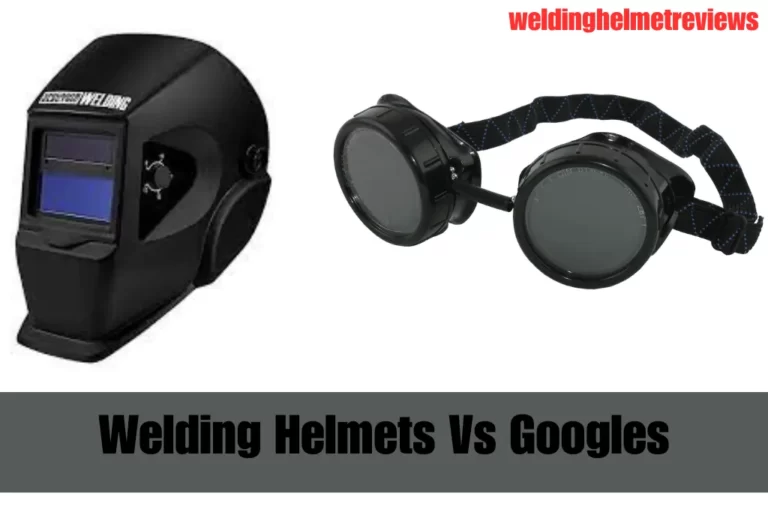

When it comes to welding, safety is paramount. One of the most critical aspects of welder safety is protecting the eyes from intense light, sparks, and debris. In the world of eye protection, two primary options stand out: welding helmets and welding goggles.

Each has its unique features and benefits, making the choice between the two a matter of careful consideration. In this comprehensive guide, we’ll explore the differences, advantages, limitations, and factors to consider when choosing between welding helmets vs goggles.

Table of Contents

Understanding Welding Safety

Welding is a skilled trade that involves fusing materials together using intense heat. While it’s a crucial technique in various industries, it also poses significant safety risks. The welding process emits powerful UV radiation, intense visible light, and potentially harmful sparks. Proper safety measures are essential to prevent eye injuries and long-term damage caused by exposure to these hazards.

The Importance of Eye Protection

Before delving into the specifics of welding helmets and goggles, let’s underline the significance of eye protection in welding. The eyes are incredibly sensitive to light and foreign objects, and exposure to welding arcs without proper protection can lead to conditions like arc eye or welder’s flash. These conditions cause discomfort, pain, and even temporary vision loss. Proper eye protection is the key to preventing such injuries and ensuring the safety and well-being of welders.

Welding Helmets: A Comprehensive Overview

Welding helmets are a staple in welders’ protective gear. These headgear devices offer full-face coverage and are designed to shield the entire face, including the eyes, from intense light and flying debris. Modern welding helmets come equipped with auto-darkening filters that adjust the level of tint based on the welding arc’s brightness.

This feature enhances visibility while providing optimal protection. The helmets are available in various styles, with features such as adjustable headbands, ventilation systems, and even powered air-purifying respirators (PAPR) integration.

Goggles for Welding: What You Need to Know

Welding goggles, on the other hand, provide a more compact and targeted form of eye protection. They cover the eyes alone, offering direct defense against UV radiation, infrared light, and sparks. Welding goggles are commonly used for specific welding tasks that require precision, such as oxy-acetylene welding and cutting. They can also be worn underneath a welding helmet for an added layer of protection.

Advantages of Welding Helmets

Welding helmets offer several advantages that make them a popular choice among welders. The full-face coverage ensures comprehensive protection against various welding-related hazards. The auto-darkening filters enhance visibility and reduce eye strain by eliminating the need to repeatedly lift the helmet. The versatility of welding helmets, with adjustable settings and additional features, makes them suitable for a wide range of welding techniques.

Read More: How to Choose a Welding Helmet

Advantages of Welding Goggles

Welding goggles excel in providing focused protection. Their compact design allows welders to access tight spaces while keeping their eyes shielded. Although there are some welding helmets for tight spaces. Goggles are often more lightweight than helmets, promoting comfort during extended welding sessions. Welding goggles also allow for clear peripheral vision, enhancing overall situational awareness.

Limitations of Welding Helmets

Despite their advantages, welding helmets also have limitations. The full-face coverage can lead to discomfort in hot environments, and their bulkiness might restrict movement in certain welding positions. Additionally, helmets can be more expensive than goggles, especially when considering advanced models with features like PAPR integration.

Limitations of Welding Goggles

Welding goggles, while offering focused protection, might not be sufficient for tasks that involve prolonged exposure to intense light. They don’t shield the entire face from sparks and debris, leaving some areas vulnerable to injury. Additionally, goggles alone might not provide the level of UV and IR protection needed for certain welding techniques.

Factors to Consider: Comfort and Fit

Comfort is paramount when it comes to choosing between welding helmets and goggles. A well-fitting piece of protective gear ensures that the welder can work efficiently without distractions. Helmets with adjustable headbands and padding offer a customizable fit, while goggles with adjustable straps cater to individual preferences.

Optical Clarity: A Vital Consideration

Optical clarity is a significant consideration in eye protection gear. Welders need clear visibility of their work to ensure accurate welding and avert errors. High-quality welding helmets and goggles come with advanced lens technologies that maintain optical clarity while providing adequate protection. Look for features like anti-fog coatings and true color lenses.

Durability and Longevity: Which One Lasts Longer?

Durability is a factor that impacts the overall value of protective gear. Welding environments can be harsh, with exposure to heat, sparks, and physical impact. Welding helmets are typically more robust due to their larger size and construction. However, advancements in materials have also made modern welding goggles highly durable and resistant to various workplace hazards.

Ease of Use: Comparing Helmets and Goggles

Ease of use plays a crucial role in welder productivity and safety. Welding helmets with auto-darkening filters simplifies the welding process by eliminating the need to repeatedly lift the helmet to check the weld. On the other hand, welding goggles are more compact and easier to don and doff, making them a preferred choice for tasks that require frequent removal of eye protection.

Welding Helmet Styles: Choosing the Right Fit

Welding helmets come in various styles to cater to different welding needs. Standard helmets offer essential protection while auto-darkening helmets with variable shade options provide enhanced visibility and convenience. For those working in high-heat environments, specialized helmets with built-in ventilation and PAPR compatibility offer added comfort.

Types of Welding Goggles and Their Applications

Welding goggles are available in different styles to suit various welding techniques. Lift-front goggles allow for a quick transition between the welding and inspection phases, making them ideal for tasks that require frequent adjustments. Cover goggles provide extended protection for the eyes and surrounding areas, making them suitable for jobs that involve intense light and heat.

Eye Strain and Fatigue: Addressing the Concerns

Extended periods of welding can lead to eye strain and fatigue, affecting both the quality of work and the welder’s well-being. Welding helmets with ergonomic designs and adjustable features can help alleviate these concerns by providing a comfortable fit and reducing the strain on the neck and head. Goggles, being lightweight and compact, contribute to reducing fatigue during tasks that require precision and close attention.

Protecting Against Arc Flashes

Arc flashes are sudden bursts of intense light and heat generated during welding. They can cause severe burns and eye injuries if not properly protected. Both welding helmets and goggles play a crucial role in shielding the eyes from arc flashes. Helmets with auto-darkening filters react quickly to changes in light intensity, while goggles with tinted lenses provide direct protection against the harmful effects of arc flashes.

Price Points: Comparing Helmets and Goggles

Cost is a significant consideration when choosing between welding helmets and goggles. Welding helmets, especially those with advanced features, tend to be more expensive than goggles. However, the investment in a high-quality helmet can pay off in terms of durability, comfort, and enhanced performance. Goggles, being simpler in design, often come at a lower price point, making them an attractive option for welders on a budget.

Personal Preference: Deciding Based on Comfort

The choice between welding helmets and goggles often boils down to personal preference. Some welders find helmets more comfortable due to their full-face coverage and adjustable features. Others prefer the lightweight and compact nature of goggles, especially for tasks that demand precision and agility. Ultimately, the decision should prioritize the welder’s comfort and ability to work effectively.

Combining Both: When Do You Need Both?

In certain welding scenarios, using both helmets and goggles might be the best approach. For instance, when performing tasks that involve overhead welding, a helmet can provide essential face and head protection, while goggles can offer additional coverage for the eyes. Such combinations ensure comprehensive safety without compromising visibility or comfort.

FAQs

Q: Can I use welding goggles for all types of welding?

A: Welding goggles are suitable for specific welding techniques that require precision, but they might not offer adequate protection for all welding methods.

Q: Are there welding helmets with built-in respirators?

A: Yes, some advanced welding helmets come with powered air-purifying respirator (PAPR) integration for improved respiratory protection.

Read More: What are the benefits of welding helmet fan

Q: Can I wear welding goggles underneath a welding helmet?

A: Yes, wearing goggles underneath a welding helmet provides an added layer of eye protection, especially in tasks involving increased risks.

Q: Do welding goggles come with adjustable strap options?

A: Yes, many welding goggles feature adjustable straps to ensure a secure and comfortable fit for different head sizes.

Q: What should I prioritize between welding helmets vs goggles?

A: Consider factors such as the type of welding, comfort, visibility, and protection level to make an informed decision.

Q: Can I find budget-friendly options for welding helmets?

A: While high-quality helmets can be more expensive, there are budget-friendly options available that still offer essential protection.

Q: Are there welding helmets with communication features?

A: Yes, some welding helmets come with integrated communication systems, allowing welders to communicate without removing their gear. Bluetooth welding helmet helps you to get a clear idea about it.

Conclusion | Welding Helmets vs Googles

In the ongoing debate of welding helmets vs. goggles, the choice depends on various factors, including the type of welding, comfort preferences, and the level of protection required. Welding helmets offer comprehensive coverage and advanced features, making them suitable for a wide range of applications.

On the other hand, welding goggles excel in precision tasks and situations where agility is crucial. Regardless of the choice, prioritizing safety, comfort, and visibility is paramount in the world of welding.

James is a welding expert, accomplished author, and trusted guide with over 8 years of experience in the industry. With his in-depth knowledge and engaging writing style, James has become a true authority in the field, offering readers and clients invaluable expertise and insights to take their welding skills to new heights.