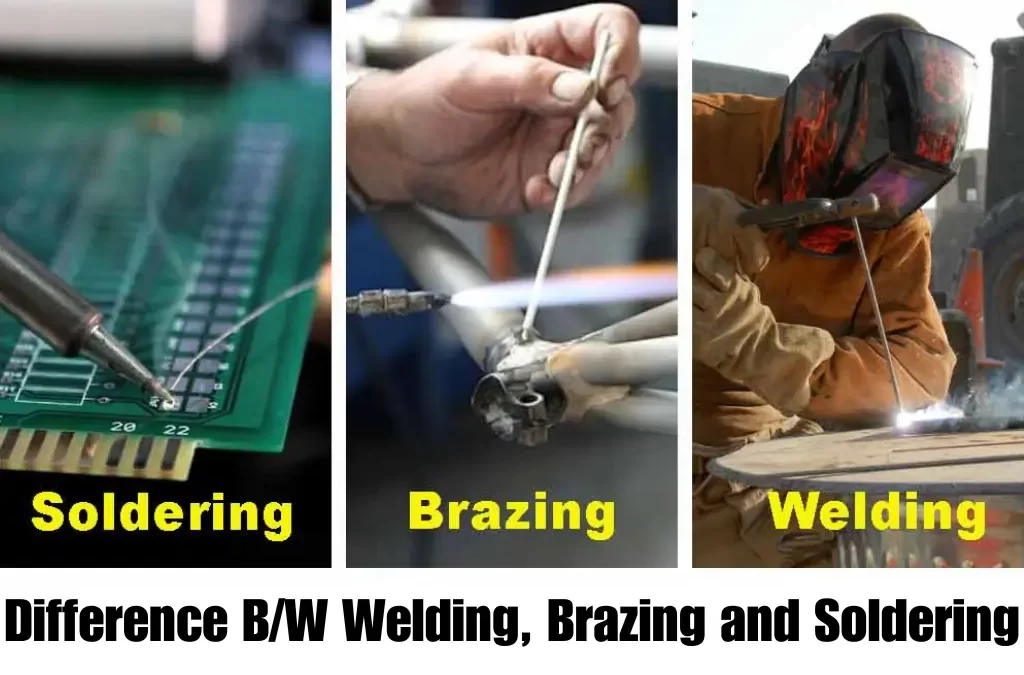

Welding, brazing, and soldering are distinct metal joining techniques, each with unique characteristics and applications. Welding involves melting the base materials and a filler metal, creating a strong fusion when cooled. It’s ideal for permanent joints in structural and industrial settings, often yielding high-strength connections.

Brazing, on the other hand, uses a filler metal with a lower melting point than the base materials. The filler flows into the joint through capillary action, forming a durable bond without melting the base metals. This method suits dissimilar metals and delicate components, producing joints with excellent integrity.

Soldering employs an even lower-melting-point filler metal, typically applied to electrical or electronic connections. The filler forms a thin layer that adheres to the surfaces, facilitating electrical conductivity. Unlike welding and brazing, soldering doesn’t create a robust mechanical bond, making it reversible.

Ultimately, the choice among welding, brazing, and soldering depends on factors such as joint strength, material compatibility, application requirements, and desired permanence.

Read More: Pros and Cons of Welding

Table of Contents

What is Welding

Welding is a fundamental metalworking process that involves joining two or more pieces of metal by melting their surfaces and allowing them to fuse together as they cool. Utilizing intense heat, often generated by an electric arc or a gas flame, welding achieves a strong and permanent bond between metals, enabling the creation of complex structures and products.

This technique finds applications across industries, from manufacturing and construction to aerospace and automotive sectors, playing a crucial role in building everything from intricate artistic sculptures to heavy-duty machinery. Welding’s versatility and strength make it an indispensable tool in modern engineering and fabrication.

What is Soldering

Soldering is a precise and versatile metal joining technique used across various industries. It involves melting a filler metal, typically with a lower melting point, to create a bond between two base materials. Unlike welding, soldering doesn’t melt the base materials but rather forms a solid connection through capillary action.

Commonly employed in electronics, plumbing, and jewelry-making, soldering ensures secure, conductive, and often reversible bonds. The process demands meticulous control of temperature and flux application to achieve reliable joints, making soldering an indispensable method for assembling intricate components and delicate materials.

What is Brzaing

Brazing is a metal joining process that involves melting a filler metal with a lower melting point than the base metals being joined. Utilizing capillary action, the molten filler metal is drawn into the joint, creating a strong bond upon solidification. Unlike welding, where the base metals melt and fuse together, brazing retains the original properties of the base metals while forming a secure connection.

This technique is preferred for joining dissimilar metals or materials with different melting points. Brazing finds applications in industries ranging from jewelry making to manufacturing intricate components in electronics and even constructing resilient connections in plumbing and HVAC systems.

Read More: What is Cold Welding

Differentiate Welding, Brazing and Soldering on the Basics of Their Properties

Welding, soldering, and brazing are three distinct methods of joining metals, each with its own set of properties and applications. Let’s compare them based on factors like strength, temperature, and other relevant characteristics:

Strength:

Welding: Welding creates the strongest joint among the three. It involves melting the base metals and often adding a filler material to create a fusion bond. The resulting joint is typically as strong as, or even stronger than, the base metals themselves.

Soldering: Soldered joints are relatively weaker compared to welded joints. Soldering relies on a lower-melting-point filler material (solder) that does not create a metallurgical bond but rather forms a mechanical connection.

Brazing: Brazing produces joints that are stronger than soldered joints but generally not as strong as welded joints. The filler material used in brazing has a higher melting point than solder and forms a stronger bond through capillary action.

Temperature:

Welding: Welding involves high temperatures, often exceeding the melting points of the base metals. This can lead to metallurgical changes in the materials being joined.

Soldering: Soldering is conducted at lower temperatures, typically below 450°C (850°F). This prevents damage to sensitive materials while achieving a bond.

Brazing: Brazing occurs at intermediate temperatures between soldering and welding, usually around 450°C to 850°C (850°F to 1560°F), depending on the filler material used.

Metallurgical Changes:

Welding: Due to high temperatures, welding can cause significant metallurgical changes in the base metals, affecting their properties and potentially creating zones of heat-affected material.

Soldering: Soldering does not cause significant metallurgical changes, as it operates at lower temperatures that do not significantly alter the base metals.

Brazing: Similar to soldering, brazing also has a minimal metallurgical impact on the base metals, but the higher temperatures can result in some heat-affected zones.

Materials Compatibility:

Welding: Welding is generally suitable for joining similar or dissimilar metals, depending on the specific welding process used.

Soldering: Soldering is typically used for electronic components, jewelry, and delicate items, as it’s well-suited for joining materials with similar properties and low melting points.

Brazing: Brazing is commonly used to join dissimilar metals with varying melting points, offering a compromise between the high strength of welding and the lower temperatures of soldering.

Welding provides the highest joint strength but requires high temperatures and can lead to metallurgical changes. Soldering is ideal for delicate applications and electronics but results in weaker joints. Brazing offers a balance between strength and temperature, making it suitable for joining a wide range of materials while avoiding extreme temperatures and significant metallurgical changes.

Final Words

In the intricate world of metal joining techniques, the distinctions between welding, brazing, and soldering are pivotal. Welding, with its formidable strength through material fusion, stands tall as the epitome of robust bonding. Meanwhile, brazing bridges the gap between strength and compatibility, uniting disparate metals with a tenacious grip. Soldering, delicate yet precise, finds its niche in electronics and intricate craftsmanship.

This exploration of their properties underscores the significance of selecting the right technique for diverse applications. Whether it’s the molten melding of welding, the capillary connection of brazing, or the intricate finesse of soldering, each method leaves its indelible mark in the world of metal fabrication.

Read More: What is Arc Welding

James is a welding expert, accomplished author, and trusted guide with over 8 years of experience in the industry. With his in-depth knowledge and engaging writing style, James has become a true authority in the field, offering readers and clients invaluable expertise and insights to take their welding skills to new heights.